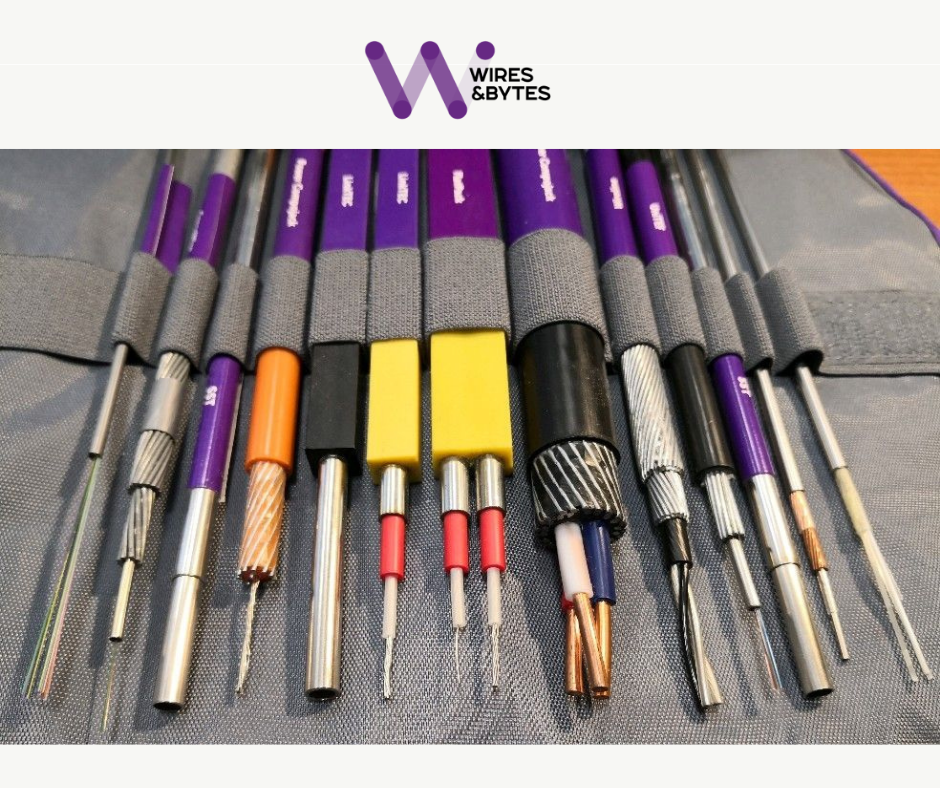

What can be more representative than a sample of a real product? Just a fine sample kit!

Wires&Bytes sample kit makes it easy to understand the WB cable range. And it’s so lightweight and handy in use: fold it, put it in a bag, and bring it wherever you need to show WB cables off!

Petar Basic, PhD, Wires&Bytes VP Technology: «All the designs in the photo are state-of-the-art designs (not older than 2 years) yet most of them are already deployed in the field by our customers. They are the results of great teamwork and efforts to meet customer expectations. Specialty cables is a mission of constant learning, challenging, widening and changing your perspectives».

Send your questions and requests here in comments or via info@wiresnbytes.com

As an Outside Sales Representative, you will be responsible for presenting and selling products/solutions to existing and prospective customers and helping to expand business in an assigned geographic territory of the North America, in particular Texas, Louisiana, and surrounding states. You will take an active part in the search for new customers, including setting up and conducting meetings. We want someone who has a successful track record with the US oil and gas well service companies. The ideal candidate has a strong understanding and experience in qualifying new suppliers and products for oil and gas service companies and has a background selling cables or related equipment for downhole applications in the oil and gas industry.

Expectations & Tasks:

Qualifications & Soft skills:

What we offer

Wires&Bytes are a community of experts in the sphere of fiber optic cables production and innovative solutions. We offer a highly collaborative, international team environment with a strong focus on new products development, offering smart solutions and recognition for your individual contributions. Apply now!

Find our samples of real Wires&Bytes products at the GOWell booth #12255 (Hall 12) as well as grab the flyer about SlickLight-C, our newest addition to the SlickLight family.

Contact us and arrange a meeting to learn more about Wires&Bytes innovative products and solutions.

Looking forward to seeing our friends and fellow industry professionals in UAE next week!

When: November 15-18

Venue: Abu Dhabi National Exhibition Centre

Hosted by the Abu Dhabi National Oil Company (ADNOC), ADIPEC is the world’s most influential meeting place for oil, gas, and energy companies and professionals.

When it comes to spooling and handling of SlickLight cables, operators should always keep in mind that SlickLight is a tube system and not a full profile wire. Correct handling of SlickLight products is crucial both during initial installation onto the winch drum and also when working on the wellsite. The winch drum must have perfectly vertical flanges, that is, the distance between the flanges at the core and at the top of the flanges must be exactly the same. This is to ensure “smooth spooling” is always maintained. If the SlickLight spooling is “scramble wound”, that must be corrected immediately so as to avoid damage to the SlickLight.

The picture below showcases the concept of smooth spooling.

Also, the recommended sheave wheel diameter is 160 times the diameter of the SlickLight. For example, a 4.6mm (0.181”) SlickLight would require a 760mm (30”) sheave, with groove diameter of exactly 4.6mm (0.181”).

The Wires&Bytes team will provide strong and timely support to our customers to ensure the best performance of this unique and amazing data collection system.

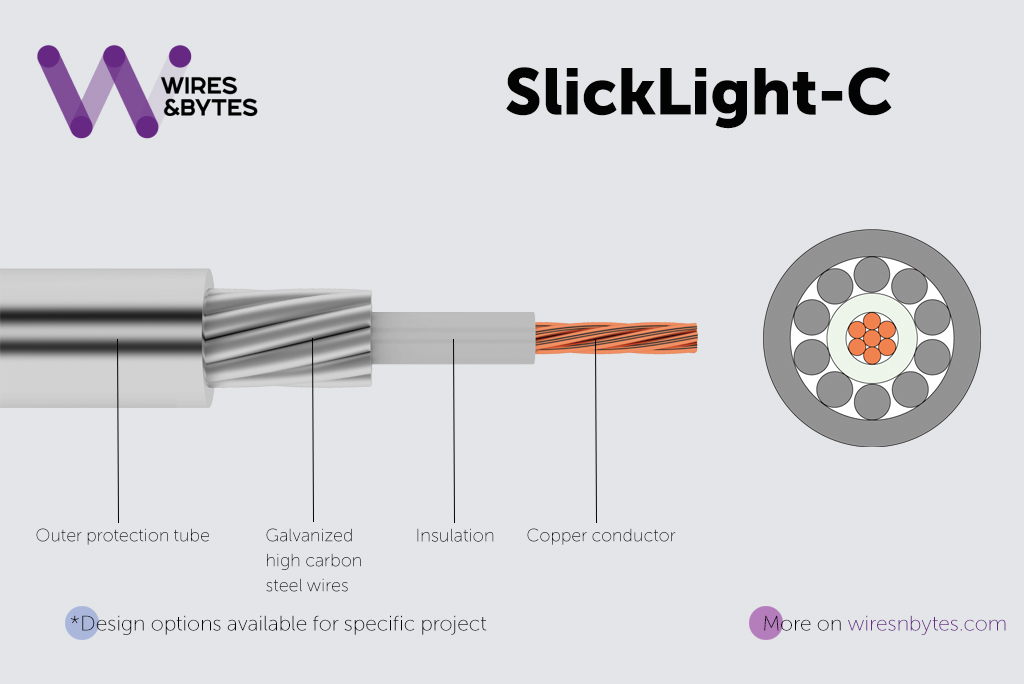

SlickLight-C is a new innovative design of downhole well intervention cable combining the flexibility of the traditional slickline with real-time downhole tool for management and communication, offering mechanical strength and features to cater traditional slickline services. The electrical conductor provides bi-directional telemetry and power delivery for the downhole tools.

Application:

Provides power to and signals transmission from downhole tools

Key features:

Benefits:

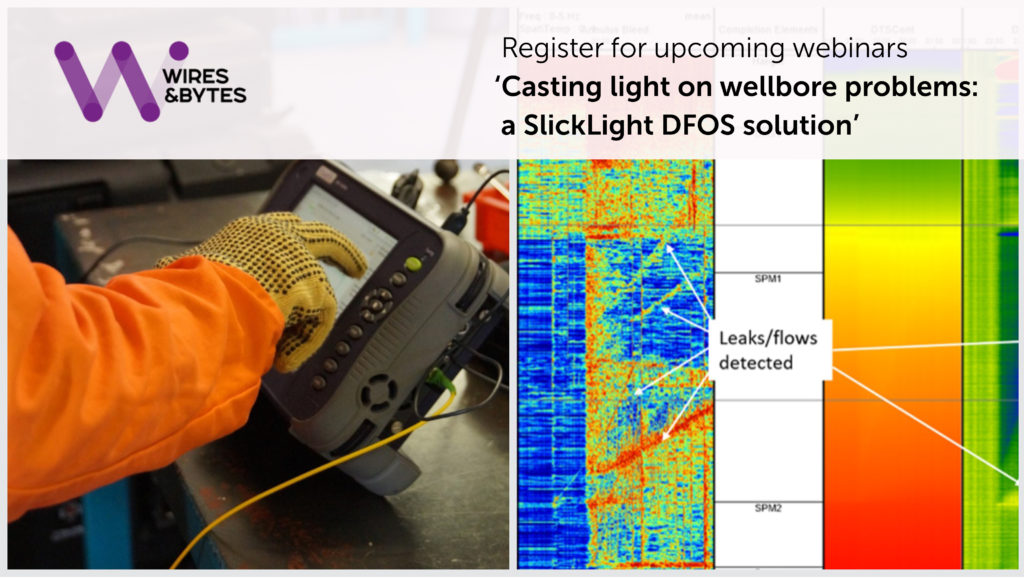

Proven in live field applications: if you use SlickLight, data management and data decimation for DFOS can be fast. It does not even matter where you are: directly on the wellsite or remotely in the office.

Decimation, or reduction of data, is particularly important for Distributed Acoustic Sensing. When it comes to DAS, the application turns SlickLight cable into a vast number of “microphones”. Can you imagine an orchestra of 500 or even 1000 musical instruments playing together while music is being recorded, processed and visualized simultaneously and in real-time? Well, DFOS data analytics can. Moreover, when this “orchestra” performs, it produces a huge amount of data that needs to be handled, visualized, and documented. It can be a real challenge.

When using decimation techniques, the analyst can easily select the relevant data and scrap the rest. This helps to reduce the amount of data while retaining all the information and makes managing the quick on-site visualization and interpretation possible. Moreover, SlickLight data acquisition requires a small number of people physically present at the wellsite. Uploading decimated data to the cloud allows office workers and remote experts to have online insight as well which is enormously helpful when teams may be scattered across the globe but need to make good decisions together based on relevant data.

In September Wires&Bytes is organizing two webinars to discuss SlickLight technology and DFOS solution to understand the wellbore problems. The presenters will discuss how to maximize the real-time well intelligence while reducing time and costs, empowering the well owners and service companies to make decisions on site in real time. SlickLight, a key component of this solution, will allow customers to offer diagnostic intervention services using DTS/DAS.

Additionally, the webinar will include live Q&A session, so let’s turn it into a dialogue!

Presenters: Petar Basic and Michael Webster

Choose the time that suits you better and register:

September 15, 3:00 pm (CET) — REGISTER

September 17, 9:00 am (CET) — REGISTER

The United States has around 3 million miles of hazardous liquid, gas distribution, and gathering and transmission pipelines in operation, and more are being built every day.

According to the report of the Pipeline and Hazardous Materials Safety Administration, in 2020, there were 578 reported pipeline incidents in the United States, resulting in the death of 15 people, injuries to another 43, and about $340 million in damages. Leaks harm the environment severely causing water and soil pollution and devastating damage to flora and fauna. Keeping the data in mind, we should also remember that statistics can never capture the full force of tragedies.

Though modern technologies allow preventing measures in a very comprehensive way!

Pipeline integrity monitoring can be conducted using DFOS (temperature, acoustic, strain sensing). The fiber as a sensitive element can track the entire pipeline length. Thus the leaks, deformation processes, or unauthorized actions can be determined in real time and with higher accuracy.

Wires&Bytes offers a range of cables for pipeline integrity monitoring:

— UniSense (can be produced with a single or double stainless steel layer)

Also here’s the video example of how pipeline integrity monitoring system can be implemented

Contact us with the details of your project and we’ll offer the solution for you!

The use of geothermal energy is an important future energy supply issue within the global strategy of sustainable development. Water and/or steam carry the geothermal energy to the Earth’s surface. Depending on its characteristics, geothermal energy can be used for heating and cooling purposes or be harnessed to generate clean electricity.

Geothermal reservoirs offer unique monitoring and characterization challenges. One of the serious problems with the use of geothermal water/steam is changes in temperature and pressure. It influences the equilibrium and leads to the scale formation on the wall surface of wells, flow lines, valves, turbines, etc. The harsh, high temperature downhole environment requires robust measurement technology with advanced features. And this is where fiber optic sensors can be utilized as a helpful tool for the application in geothermal wells! Remote operation, small sizes and robust design are being of particular importance and among the inherent advantages.

Over the past decade DFOS has evolved from a new to a prominent geophysical tool with still ever-expanding applications. This is extremely useful to measure continuous temperature and pressure profiles in the subsurface for geothermal exploration. Both DTS and DAS, and even DSS features can be integrated into a single cable design and conduct multiple fully independent measurements simultaneously thus providing independent data for the same perturbation. Using the same design and one time installation for acquisition of different data brings economic benefits for the operators.

Data received from fiber optic sensors can be used in defining the intensity of the thermal anomalies and setting a long-term monitoring system that enables transferring geothermal energy more effectively.

Among the designs offered by Wires&Bytes SensoWire, SlickLight and MultiSense can be used for geothermal monitoring. SensoWire is more traditional and suitable for DTS and DAS applications whereas MultiSense and SlickLight are more innovative and raising significant interest in the industry, providing various asset health monitoring applications. In terms of geothermal monitoring MultiSense can be exploited for acoustic, seismic and well structural health monitoring using its DSS feature (to monitor the integrity of the wells). Currently MultiSense is being deployed and trialed in the geothermal well in Germany. Stay tuned for updates!

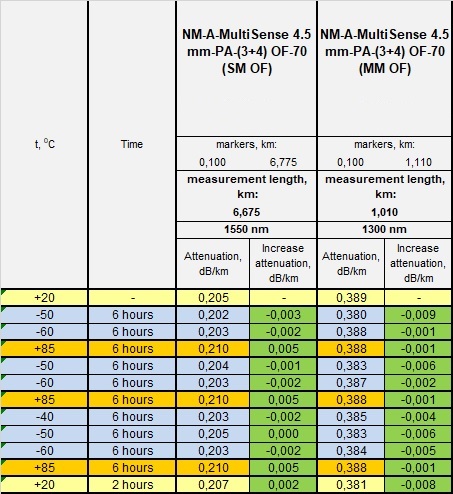

In early July one of the Wires&Bytes brand-new designs — Non-Metallic MultiSense — passed the climatic test successfully and confirmed its operation temperature range from -60°C to +85°C.

The test lasted for 6 hours, and the cable withstood 3 cycles of exposure to temperatures from -60°C to +85°C. This potentially means that Non-Metallic MultiSense can be used in different environments having almost no restrictions in outdoor installations. Particularly the cable can be buried in the ground or integrated into structures such as roads, concrete beams and slabs and withstand sub-zero temperatures while providing quality strain temperature and acoustic acquisition data.

This time the cable samples were wound on a plywood spool. The second step of the planned climatic tests will be conducted with a coil of a cable. We’ll keep you posted on results!

Non-metallic MultiSense is a design with a gel-filled central PBT loose tube with optical fibers freely placed inside with 4 tight-buffered optical fibers, FRP rods, and outer jacket suitable for all types of DFOS systems and distributed monitoring as well as for simultaneous multiple measurements along with fibers for data communication. Learn more

Also dig for: