There have been many serious bridge disasters throughout history.

Why do bridges collapse?

The history of bridge construction and catastrophic failures has taught us a lot of things, but especially to think about safety first. Lessons learned: all the problems listed above can be tracked! Early detection of damage leads to prevention of critical issues and structural faults, reducing repair time and costs, and most importantly saving peoples’ lives!

Wires&Bytes offers a range of cables for structural health monitoring: Non-metallic MultiSense, UniTEF, SensoWire, and others. Discover more on our website.

Wires&Bytes welcomes a new team member — Thomas Utz who is joining us as a Director of Wireline Products.

Tom is based in Houston, Texas and is joining the rapidly growing US office of Wires&Bytes. He has been working in the Oil&Gas market for the last 40 years and has extensive experience in wireline industry. He previously worked at such companies as Rochester Corporation and Kerpen Kabel, Camesa and WireCo group and well-known in the industry.

With any sales and product inquiries, please contact Tom via tom.utz@wiresnbytes.com

Welcome onboard, Tom! Having you with us means a strong commitment from Wires&Bytes to grow our customers base.

Fiber optic cables are now routinely deployed for condition monitoring purposes, making them not only a reliable, sensitive, and smart source of information but also a medium to transfer data to the control room from the remote locations.

Introduction of multisensing cables allowed the customer to sense and transfer multiple sensing data, which was the key motivation behind the development. The new cable will decrease the installation and maintenance costs, optimize equipment operation, provide faster emergency response, reduce environmental damage, etc.

Advantages:

👉 Visit the page to take a look at the video, where the process of Oil&Gas well downhole monitoring is shown and learn more

Last week we unveiled a Non-metallic MultiSense cable, today let’s take a closer look at its applications.

MultiSense is not just an eye-catching name, it provides a platform to monitor different physical changes with a single cable. Non-metallic version is fully dielectric (it cannot be revealed by metal detectors!), making it safe to use where electric current can be an issue. If you need a more robust cable with higher tensile strength, it can be encapsulated in stainless steel.

This cable can be produced in two options:

Where Non-metallic MultiSense can be applied:

Are you looking for a cost-effective solution and interested to discuss the options for your project?

Send us a request via website and our sales team will provide you with the details!

Compact but multifunctional, Non-metallic MultiSense makes a change in the world of distributed sensing.

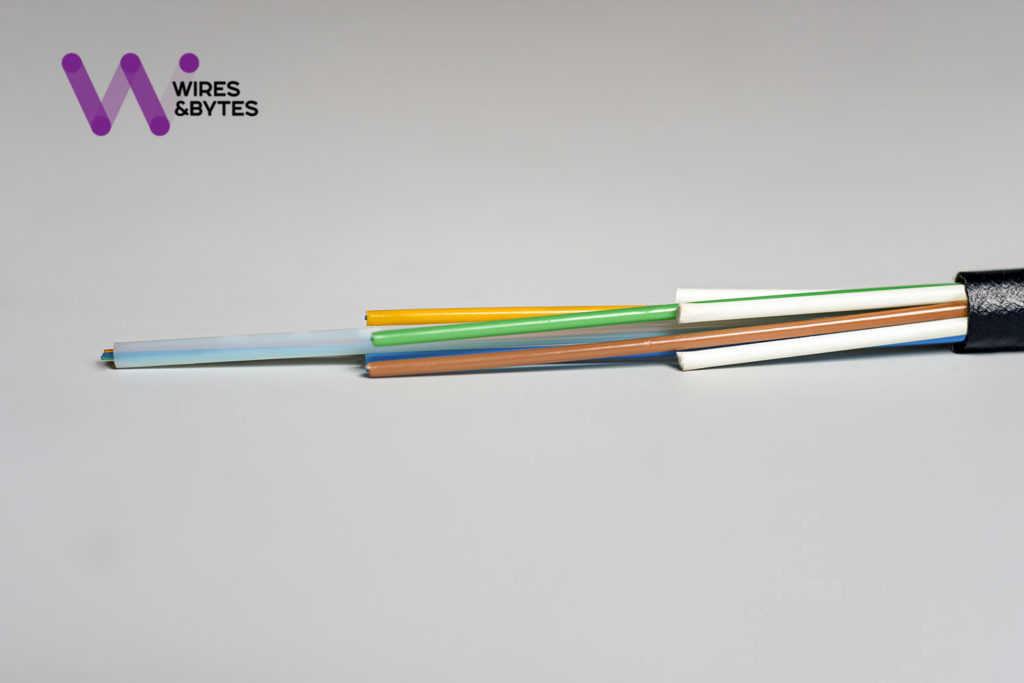

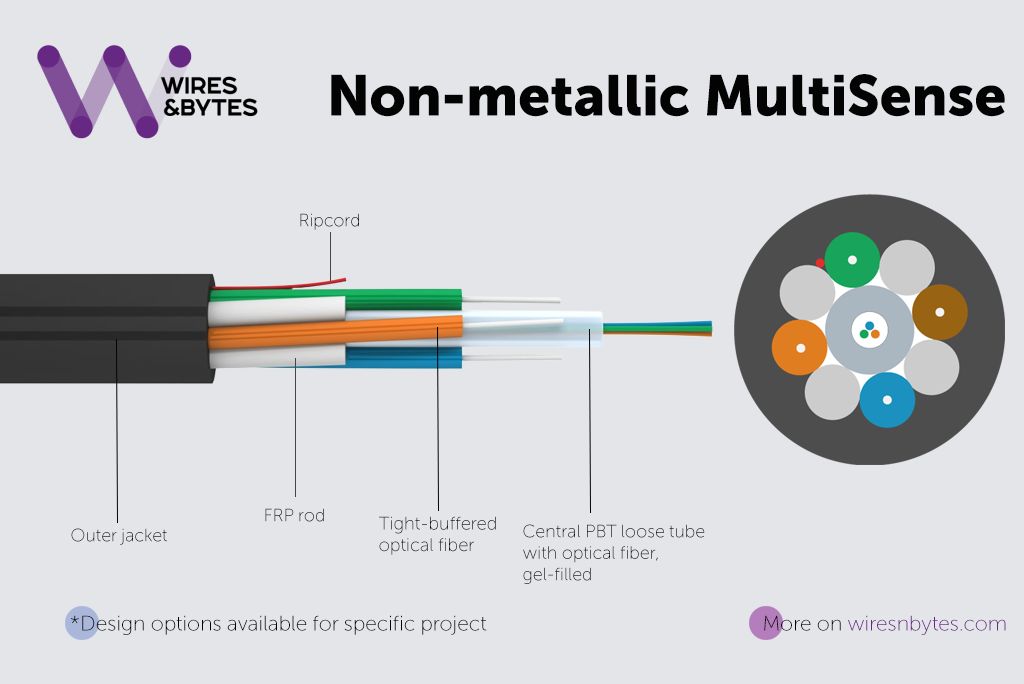

Despite its considerably small size and low weight, it is able to support all types of DFOS technologies and deliver multiple measurements. You might have already seen our Metallic MultiSense, but today let’s take a look at this design.

Non-metallic MultiSense is a combination of a gel-filled central PBT loose tube with optical fibers freely placed inside with 4 tight-buffered optical fibers, FRP rods, and outer jacket.

Please note that we design cables based on our customers’ specific technical requirements. In case of Non-metallic MultiSense besides any other requirements, the standard lay length may also be changed according to the project needs.

If you are interested in MultiSense and would like to learn more about it, please send an inquiry via website.

Wires&Bytes will commission a new production line to provide thick-wall tubes for our cables starting this autumn.

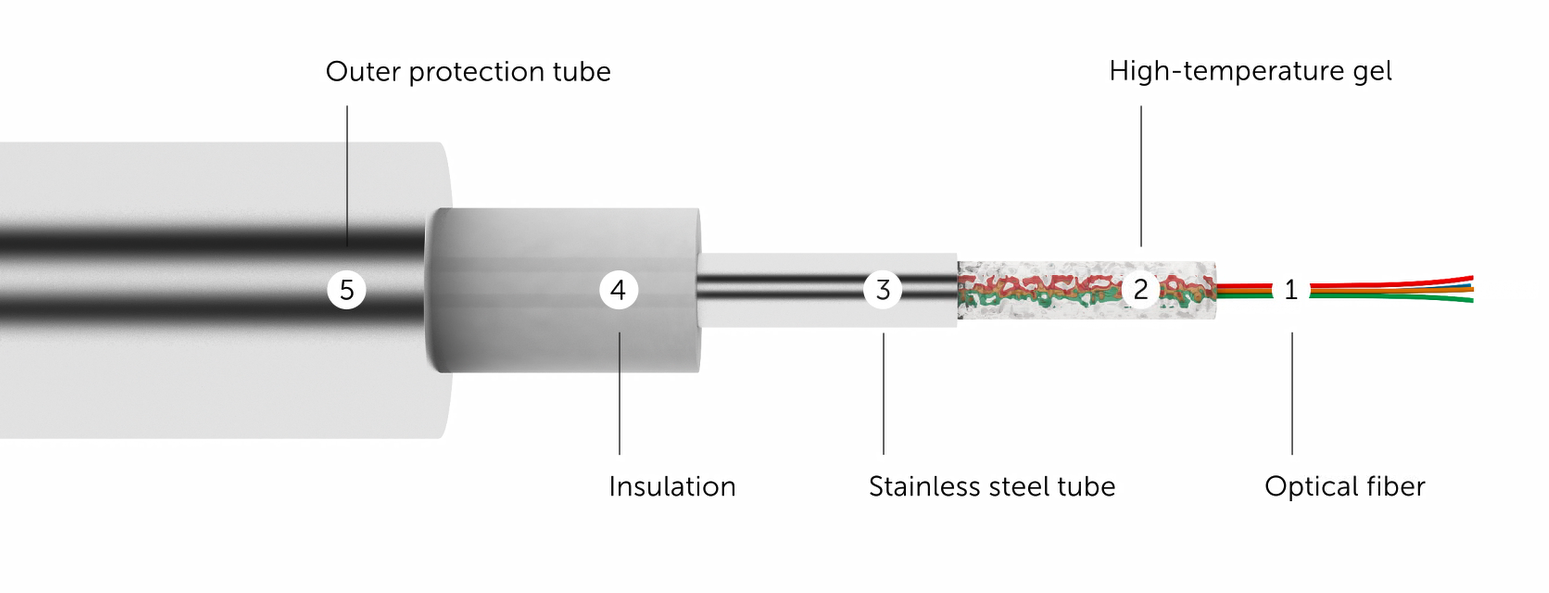

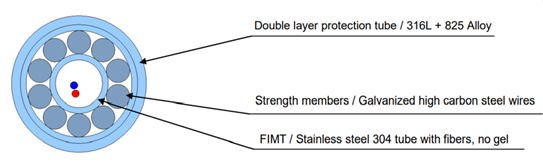

This is the culmination of design, technology, and investment targeted to meet our market and customer demands for longer, stronger, more reliable, and cost-competitive cables. We have worked closely with machinery suppliers to develop a state-of-the-art production line including forming the tube, superior welding technology, and quality control features. The new technology will offer cables which slick, gas-tight, and better sealing process on well head characteristics.

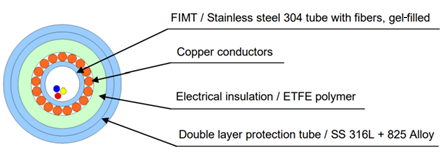

Take a look at our animated video to explore the thick-wall steel encapsulation tube design in detail (overall OD = 4.00mm with wall thickness of outer encapsulation around 0.8mm).

👉 If you haven’t had a chance yet, read our article about the distinguished features of the thick-wall small diameter steel encapsulation tube.

👉 Contact us for details on how this technology can improve your well logging experience, increase your ROI, and reduce TCO (Total Cost of ownership) at the same time.

Please let us know how we can help you to implement it in your location.

20 Jan 2021

Today’s oil and gas industry challenges require companies to deploy the most up-to-date technologies or upgrade the current ones as an alternative to the traditional mechanical wireline services.

Standard slickline servicing for the oil and gas industry can provide an effective well maintenance by deploying and manipulating the downhole tools. For many decades, slicklines and wirelines are used in well interventions that provide data with limited accuracy and acquisition frequency. The results depend very much on the skills of the operator and the quality of used tools. With the introduction of new disruptive technologies, these limitations have now overcome, for example, with the introduction of fiber optic (FO) slickline — the slickline/wireline becomes a distributed sensor along the whole length hence turning the full length of the slickline into a dense chain of passive segments, each one transformed into measurement gauge sensitive to external perturbation and physical quantities, detecting and measuring temperature, sound/acoustic, strain and pressure.

Wires&Bytes, which is at the forefront of the technology, have looked ahead and developed and offer FO slicklines and FO wirelines based on advanced fiber optic distributed sensing technology, DFOS. Wires&Bytes slickline tracks and monitors well activities delivering cost-effective data from the downhole allowing to make the quickest desicions for operators and owners, in many cases at wellsite.

The timely availability of well health information is critical to the oil and gas companies, where decisions hinge on the availability of useful data to implement it quickly and efficiently. The DFOS based slickline and wireline is an efficient and reliable tool, saving time and operating cost to the well operator, providing real-time information from the wells through an intelligent monitoring and allowing to identify and rectify issues and flaws in a timely manner.

Are you ready for advanced fiber optic sensing for precise well data at the speed of light? Let us know all your requirements and we will provide you with the monitoring solutions which are reliable, cost-effective and would increase your Return-on-Investment (ROI).

For further read, please go for Wires&Bytes “Slickline Measurements: The Future is NOW!”.

17 Dec 2020

In autumn 2021 Wires&Bytes starts a new chapter in steel tubing and will introduce thick-wall steel encapsulations mill while keeping the production efforts and related costs low. Predicting possible thoughts on the topic, our today’s post addresses the questions such as what the distinguishing features of thick-wall tubing are, and what benefits it brings to the customers.

The fact is that we increasingly receive the following requirements from the clients:

To tackle these challenges emerging from various applications Wires&Bytes has been closely working with machinery suppliers developing advanced welding techniques for improved steel encapsulation especially addressing small outer diameters and long lengths.

The result is a new mill tested and proved in the EU labs now planned for commissioning and putting into operation this autumn. So more posts in the future addressing this thick-wall steel encapsulation technology are planned and your comments and questions are welcome.

09 Dec 2020

With the availability of fiber optic and optic/electric slickline there are multiple new services that can be offered using existing idle assets. Fiber optic measurements offered by these slicklines provide wellsite answers and allow immediate optimization of production and clearly identify production problems, thus allowing customers to develop and implement an economic plan.

SLICKLINE CAPABILITIES

Fiber Optic Cable

Wellbore integrity (DTS/DAS)

Production monitoring (DTS/DAS)

Frac monitoring

Seismic profiling

4,6 mm (0.181 inches)

Working load limit — 2130 lbs

Electrical/Optical Cable

Well integrity with dual measurements

Electric line services

Advanced logging depends on power/telemetry requirements

Tractor in horizontal wells

Plus all fiber optic per fiber cable

4,8 mm (0.189 inches)

Working load limit — 1110 lbs

No grease injection required

👉 Use fiber optic slickline to put your idled assets back to work providing a technical solution for today’s production challenges.

Contact us for details.