Our industry tends to think of slickline as a low tier option to make largely mechanical changes to the well later in its life. With the development and continuous improvement of memory tools there has been an ever-increasing role of slickline to deploy memory tools and later retrieve the information for analysis and interpretation.

We believe we are on the verge of a significant change in the way slickline is used and perceived. The evolution of slickline started with the first fiber optic slickline (~2010) when a Distributed Temperature survey (DTS) was deployed from a slickline drum into wells to measure flow profiles and do gas lift optimization. That huge step turned the entire line into an instrument which measured temperature along the full wellbore in real time. We saw that the performance of the reservoir was not static and gas lift valves chattered, opened and closed and rarely functioned exactly as designed.

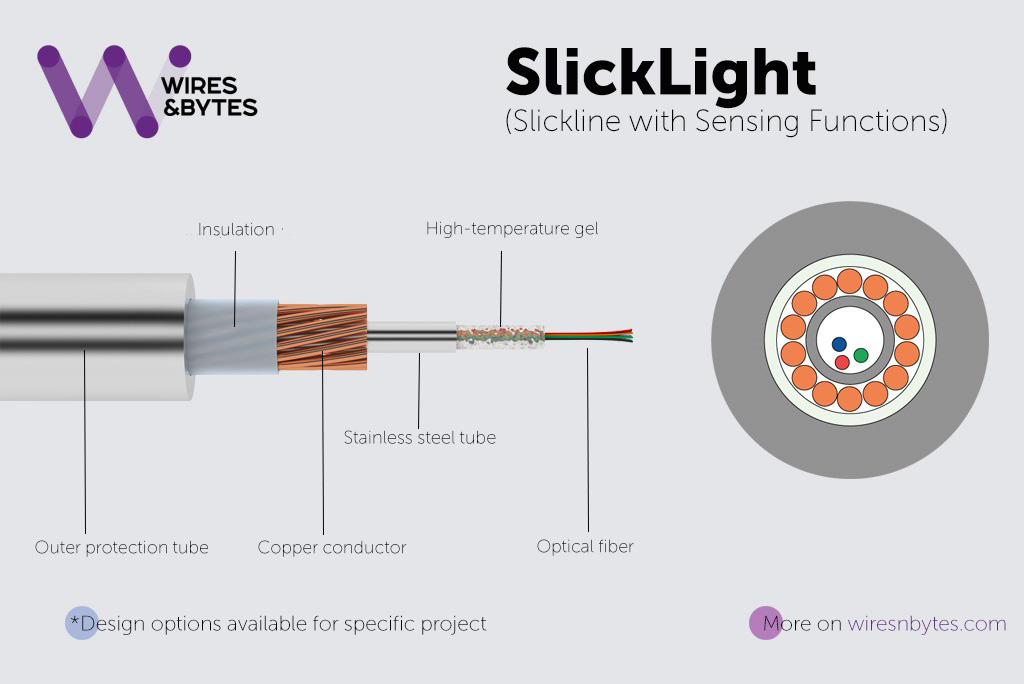

Fast forward to today where Distributed Temperature Surveys (DTS), Distributed Acoustic Surveys (DAS) and an electrical signal can all be built into a single 4.8 mm (0.189 inch) or smaller line.

The possibilities are endless:

— Depth correlation via traditional gamma ray collar locator tools

— Flow profiles using DTS and DAS to give quantitative flow from perfs in non-horizontal wells

— Injection profiles from warm back data

— Leak detection using DAS and DTS

— Gas lift monitoring of the entire system at the same time – no station stops at a moment in time

— DAS to monitor for microseismic events from a nearby frac well to get frac height

— DAS to monitor strain and microseismic from an offset well for frac growth and prorogation

This new slickline technology combined with easy-to-use software and acquisition units will change the slickline industry to one where complex well analysis can be done in real time from the wellsite. Gas lift wells are run at the optimum production rate, frac analysis and modeling can be verified and improved for the local geological impacts.

Contact us for details on how this technology can improve your production and how we can implement it in your location in a cost-effective way to get answers quick.