Structural health monitoring systems aim to provide information about any significant change or damage occurring in a structure. The key purpose of structural damage detection is to identify the reason, location, and type of damage, and then to measure the damage severity and predict the structure’s service life and behavior. Different types of structural defects can be caused by internal factors (corrosion, fatigue, ageing, etc.) and external factors (earthquakes, wind loads, soil movements, etc.). Any type of defect may lead to collapses.

One may say that nothing is eternal, but when it comes to the pieces of Ancient and Medieval architecture, science and technology must be as innovative as possible in terms of preserving cultural heritage for future generations. And here comes the fiber optic technology that offers DFOS monitoring. Understanding the structural behavior of heritage buildings is usually a very complicated task because they typically present complex deterioration and damage patterns.

So let’s take a look, for example, at The Leaning Tower of Pisa. The Tower of Pisa, which is the bell tower of the city’s Cathedral, began tilting during its construction in the 12th century, due to an inadequate foundation on the ground that was too soft to properly support the structure’s weight (there used to be a river in the area; the name Pisa is Greek for ‘marshy land’). The tilt increased in the decades before the structure was completed in the 14th century.

The Leaning Tower of Pisa was stabilized with a massive engineering operation that took place in the 1990s and lasted over a decade, in the attempt to stop the monument from falling. In fact, by the end of the 1980s, the Tower was slowly heading toward its catastrophic collapse.

The solution to this problem was found in reinforcing the soil under the foundation and making room for the Tower to compress some of the soil and straighten back up towards the North (the Tower leans to the South). In theory, it would be possible to straighten it completely, but nobody really wanted that. The Tower was born leaning and should have remained leaning.

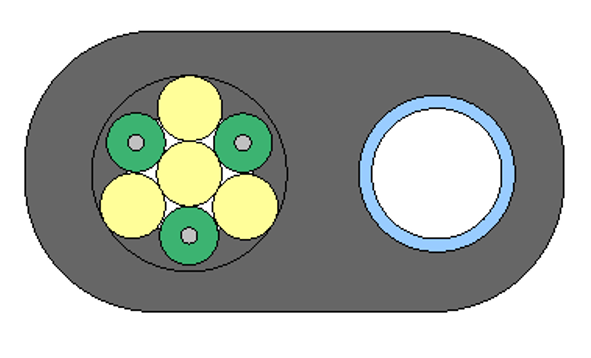

And to keep this leaning safe in the future the Tower needs continuous surveying to assess its stability. With the help of structural health monitoring, let’s say! DFOS monitoring can track and record both soil movements and the monument behavior horizontally and vertically all along the cable length. MultiSense is the perfect solution in this case as it is extremely sensitive and can provide loads of useful data to a monitoring specialist and data analyst.

SlickLight-C is a new design of downhole well intervention cable, which combines the flexibility and mechanical strength comparable to traditional slickline with real-time downhole electrical tool management and communication with use of central electrical high temperature conductor offering both bidirectional high-speed telemetry and power delivery.

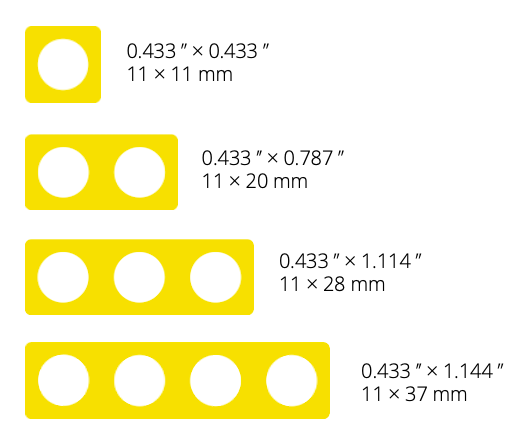

The small round-shape slickline design offers low friction and low abrasion with no need for expensive grease and pressure control equipment on the well site. The standard slickline dual pack-off pressure control equipment is all you need. The central conductor is a stranded type. This stranding works in conjunction with the upper steel round wire stranding for a better bending performance and a longer lifetime. Various types of polymers can be applied on top of the copper wire strand, with 200°C Fluorinated Ethylene Propylene (FEP) being the standard option.

The stranded steel wire layer and the final round outer steel tube define the mechanical performance of the overall construction. The low-footprint design aims to offer high-speed communication, fast battery charging and electrical powering of logging and downhole equipment.

The innovative SlickLight-C technology is bridging the gap between a cased-hole electric line and standard slickline services and represents a further step towards real-time full-length logging and profiling. This technology empowers the users to make immediate decisions at the well site, while performing both electrical and mechanical services.

𝘎𝘦𝘵 𝘪𝘯 𝘵𝘰𝘶𝘤𝘩 𝘵𝘰𝘥𝘢𝘺 & 𝘸𝘦 𝘸𝘪𝘭𝘭 𝘣𝘦 𝘢𝘣𝘭𝘦 𝘵𝘰 𝘢𝘥𝘷𝘪𝘴𝘦, 𝘴𝘶𝘱𝘱𝘭𝘺, 𝘪𝘯𝘴𝘵𝘢𝘭𝘭 𝘢𝘯𝘥 𝘴𝘶𝘱𝘱𝘰𝘳𝘵 𝘺𝘰𝘶𝘳 𝘰𝘱𝘵𝘪𝘮𝘢𝘭 𝘴𝘰𝘭𝘶𝘵𝘪𝘰𝘯.

At Wires&Bytes we are constantly moving forward with our designs, while also taking into consideration multiple different aspects of what our production should include. Nowadays, when the issue of environmental protection is as acute as ever, we would like to share the ideas of our contribution to this key element.

Going green means being efficient

The newest development – thick-wall SlickLight is going to change the way things are organized on well sites. While keeping the size of the SlickLight the same as traditional slicklines, and back-compatible with traditional and standard equipment, it will use the cross-section of the SlickLight more efficiently and increase the tensile strength. This applies to all SlickLight products: copper-only, fiber optic only, and hybrid, having copper and fiber optic together.

Furthermore, with the increased working strength it will be possible to provide data acquisition for deeper wells using slickline technology.

These factors contribute to lower fuel and energy consumption and fewer emissions for well intervention jobs. The operators will be able to achieve more with the same equipment and resources on the well site. It takes modern production technology to combine efficiency in operations, environmental protection, and the acquisition of quality data.

The new line will be commissioned this autumn. For now, you can check out the beauty of the current production line.

Fiber optic based technology can be used as an unmatched tool for monitoring, detecting and analyzing the deformation in soil slopes or any type of ground movement during the pre-failure stage. It is crucial to monitor hazard-prone regions to save human lives and assets. The effectiveness and sensitivity of DFOS technology are promising for possible use as a reliable early warning and forecasting system. Also, it can play a crucial role in the construction and post-construction period of engineering projects such as tunnels, pipelines, bridges, or open road cuts.

Exploiting its high spatial detection range (up to 2 km of fiber length) the sensor cable can be deployed all across the potentially unstable areas even when their location is not known apriori, and to measure the displacement of the unstable soil mass with respect to the stable ground along the cable length. Thanks to its high sensitivity and spatial resolution, the sensor cable can detect and monitor the development of small strain within the ground movement.

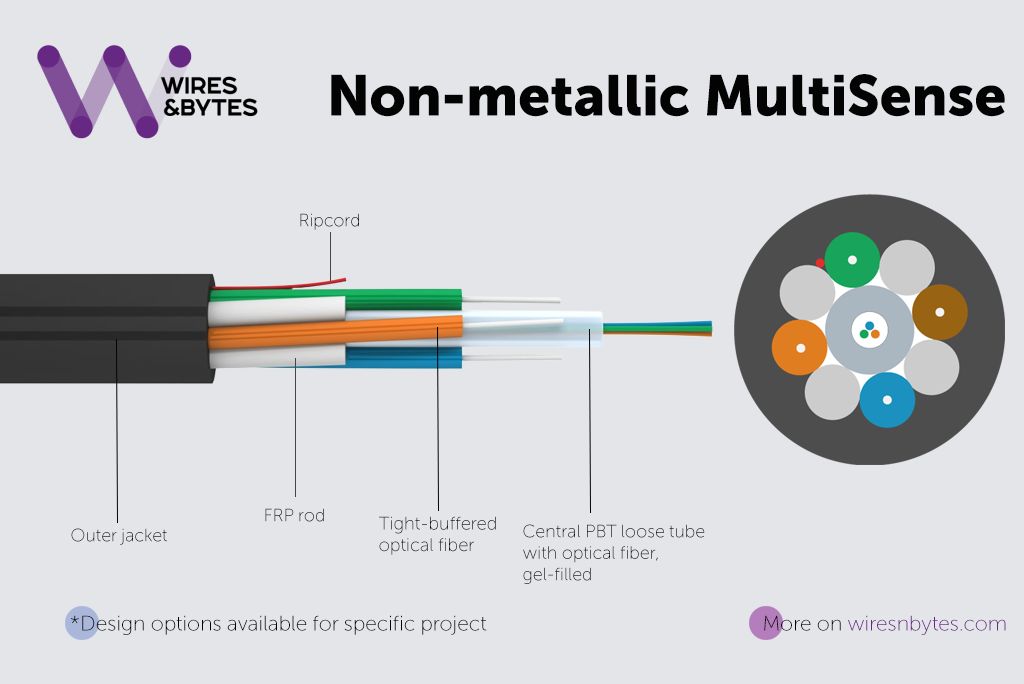

Wires&Bytes offers a number of cables that serve for detection of slope or ground movements such as Non-metallic MultiSense, UniTEF, or CreepGuard.

MultiSense product fits well to this application as it combines strain-coupled and strain-free fiber configuration. Strain sensing fibers in the armor layer can be stranded to the customer specified helix lay-length, tuning the strain sensitivity of the cable and customizing it to a magnitude, exceeding the physical possibilities of uncabled optical fibers. For strain values beyond 1% we recommend considering the deployment of loose tubes in the armor layer. For all the other strain rates equal or lower than 0.15%, the central loose tube will be needed for temperature compensation or for organizing the loop for stimulated Brillouin scattering interrogation.

Further, its unique feature of pressure-strain transduction, MutiSense cable is acoustically very sensitive to pressure changes in the environment, in this case with the soil in which it is deployed. This feature needs only 1 single-mode fiber in the stranded layer, and it will provide even more useful data to a monitoring specialist and data analyst, which will be unprecedented and critical for future decisions. Both in the lab and in the industry MultiSense has been proven to exhibit high seismic sensitivity using standard telecommunication fibers only and this contributes to the cost efficiency in the projects. The sensitivity is comparable with Rayleigh backscatter enhanced optical fibers and it can be extensively used when the cable is deployed in the soil for various and independent data acquisition.

Explore relevant fiber optic cables on our website

𝘎𝘦𝘵 𝘪𝘯 𝘵𝘰𝘶𝘤𝘩 𝘵𝘰𝘥𝘢𝘺 & 𝘸𝘦 𝘸𝘪𝘭𝘭 𝘣𝘦 𝘢𝘣𝘭𝘦 𝘵𝘰 𝘢𝘥𝘷𝘪𝘴𝘦, 𝘴𝘶𝘱𝘱𝘭𝘺, 𝘪𝘯𝘴𝘵𝘢𝘭𝘭 𝘢𝘯𝘥 𝘴𝘶𝘱𝘱𝘰𝘳𝘵 𝘺𝘰𝘶𝘳 𝘰𝘱𝘵𝘪𝘮𝘢𝘭 𝘴𝘰𝘭𝘶𝘵𝘪𝘰𝘯!

Picture credit: Oregon Department of Transportation

For Wires&Bytes 2021 was the year when we welcomed new members, one of whom is Dr. Petar Basic, an expert in fiber optics taking the position of VP Technology. We would like to share this extensive interview with Petar where he talks about his work, plans, focus and the engineering mission of Wires&Bytes.

Petar, you joined W&B as a VP technology, tell us please about your previous experience.

My career started in 1998. I majored microwave engineering and graduated in 1997. In those days I was dealing with computational electromagnetics, microwave antennas, wireless transmissions etc. Just about that time fiber optics started getting high momentum and I decided to switch to that field. My first involvement was helping new telecom operators to define, plan and design fiber optic networks in their efforts to introduce the broadband. Much of that was the hybrid fiber-coax technology at that time. As a consultant I worked with companies in Europe and overseas on starting and adapting new concepts and implementing the technology in their projects. I always liked to read the literature on the topic and had a chance to meet in person the pioneer in fiber optic sensing, Professor Alan Rogers. His books brought me to the field of distributed fiber optic sensing (DFOS). He sparked in me the passion of using optical fibers in measurements and sensing and I have been spreading it ever since. Simultaneously I completed my MSc and PhD and used it to introduce some further concepts resulting in several deployments in different parts of the world.

Why did you decide to join Wires&Bytes?

What I like about W&B is an entrepreneurial and ready-for-any-challenge mentality that is seeking new opportunities, willing to innovate and propose products that will be a solution to someone. The mindset was the main reason for my decision. In addition to that was a modern, capable and growing production facility and family atmosphere there.

The cable range of W&B includes different kinds of specialty cables. Could you tell us about your personal favorites?

In the sphere of Structural Health Monitoring (SHM) it is Non-metallic MultiSense (NM-MS). In a nutshell it combines two important features – stress-free fibers and stress-exposed fibers, both in non-metallic design. Combining these two is generally considered challenging to manufacture, as production must work smoothly on longer lengths and optical losses must be kept low. There are quite a few features we can possibly integrate and introduce in the MultiSense; today using standard and tomorrow with various high temperature polymers. The second would be the logging slicklines developed with our UK partners; electric, fiber optic and hybrid for downhole applications. The challenge here is to have the smallest, strongest and lightest designs with all the features the customer is expecting to have, and yet it must remain compatible with traditional downhole intervention equipment.

And concerning the “customer” question. Could you please tell what is the process of starting and getting the product ready for the market?

It starts in two ways: first, internally born ideas – in which we rely on our experience and knowledge and use them to develop new concepts, and second is externally born ideas, as the result of communication with the clients, listening to their plans, wishes and ideas, and then trying to address them with our capabilities and capacities. If one can combine both, one cannot miss success if opportunities are given.

And on average how long does it usually take to make a product?

I’d say development of a feasible and doable product can be anything between 3 months up to around 3 years in my own experience. Sometimes it takes quite a lot of time to find the right materials on the market and manage the resources. It may require building a testing facility from scratch for some challenging designs to avoid walking in the dark and get good feedback and directions for the next step in R&D.

What would you like to bring to Wires&Bytes?

Within the scope of our production capabilities, I see opportunities and focus on few specialty designs. I would define the features of these cables as – rich, stable, cost-effective which the customers can rely on. Ideally, they will be something that other companies can adopt and use to develop their technology and new applications. If we make our products affordable and simple, I expect we will increase the acceptance of our products in the market. That is the scenario I would like to see developing and that will be my contribution to W&B.

What will it eventually mean to the industry and the world? Will it be a safer place or a better place?

People traditionally see cables as something that is long, black, and ultimately simple. I believe this viewpoint will change as new features are added. As the equipment is directly exposed to conditions that can be extremely harsh it must stay there and operate for many years. Smart design and top quality are the only way forward for many cable productions. In many cases digitalization and virtualization start with the smart cable. And digitalization is a fast-running train today. Cables will inevitably be a part of that. Wherever we will be able to deploy “smart” cable, whatever kind it may be, we will have the means to acquire quality data without a necessity to be physically present there at the location. The cables will make “smart” the whole context in which there are integrated. Getting the data and information will help avoid dangerous situations, hostile environments for humans, and predict events including dangerous or catastrophic ones. Anything like bridges, tunnels, power lines, pipelines, pipes, geotechnical fields etc. should be digitalized and able to provide the data, all of that with low costs to be widely adopted.

I assume cables that Wires&Bytes produce are the cables of the future. Another important thing for the future is the green energy and we need to consider it as well while doing business. What are your thoughts?

We see that the world shifts to low carbon emission and energy-efficient economy. Smart, features-rich cables are the way into the future for cable manufacturing industry. DFOS systems have a lot to contribute there. In case of fiber optic cables, the only equipment that needs energy is a measurement unit sending the light into the cable and detecting backscattering or reflected light carrying the information. This works over very long distances and with a huge number of measurements points. The cable works for you there where you previously needed to provide energy source to power the equipment or needed to reach the place with the car or helicopter or ship. DFOS systems are intrinsically energy efficient and, in some cases, your only option.

What inspires you in your job?

I am always in search for simplest but good ideas that will help you make the next step. The inspiration can come from seeing it from other people, but also from reading books, from professionals in different fields and not only engineering, also from philosophy, art, literature, science, and religion. The inspiration is everywhere, and the real beauty of it is that you can find it in completely unrelated disciplines and then use it in your daily job in a new way. This brings colors to the daily job and life and it confirms the saying “find a job you enjoy doing and you will never have to work a day in your life” and in my opinion it’s absolutely true. This is maybe the key for what is called “a success”. In that respect travelling and meeting new people and cultures helps widen the mind and broaden the views and get new inspirations. The optical cables have helped a lot in these Covid-19 times when travelling was limited!

What is the mission of Wires&Bytes?

Using the cliché I would say the mission is to deliver the best quality, on time, with an affordable price for the customers. But there is more, of course. For W&B it is extremely important to deal with and understand the whole picture: from the needs in the applications, down to the details in the production. All these things are necessary to be recognized as the leader, and becoming the leader is the mission of Wires&Bytes.

26 May 2021

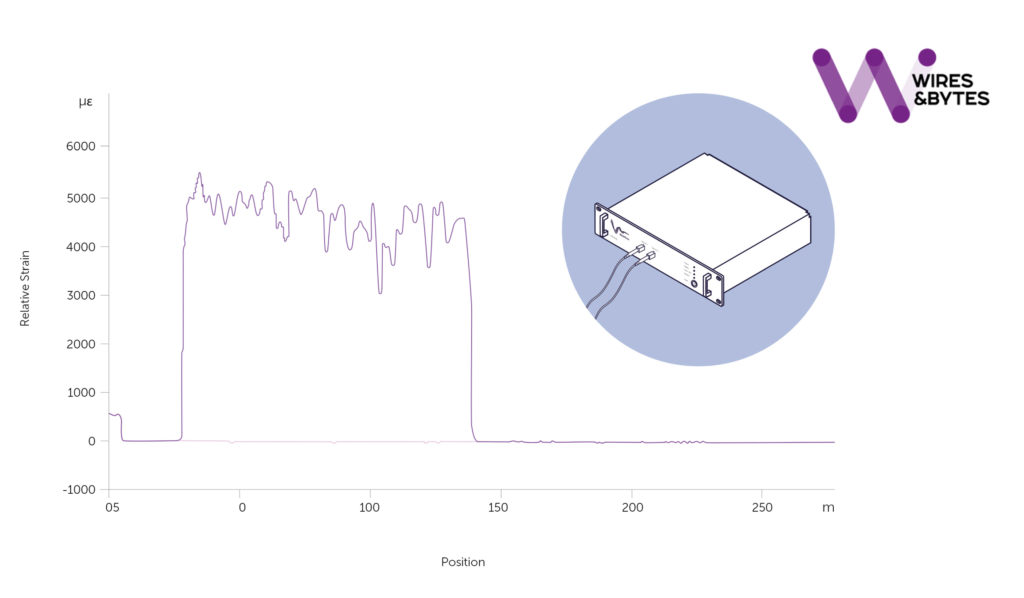

Mechanical properties play a critical role in defining fiber optic cable reliability and life expectation. One of the key measurands which dictate mechanical reliability is the residual strain in the final cable after it is manufactured. Wires&Bytes measures distributed strain at the in-house Test Centre to study residual strain in their cables before shipping to the end customer. This is an extremely valuable measurement tool that can help to understand the cable mechanics in depth, for example, predicting the lifetime of optical fiber and fiber optic cables in applications.

At Wires&Bytes cables are tested with a Brillouin analyzer which enables measuring the distribution of mechanical stress and fiber elongation along the entire length by the following techniques:

What we measure:

How you benefit:

The experience and data gained from the Brillouin analyzer help us in advising customers how to deploy cables in the most efficient way and with the best installation methods.

Need more details on that? Send us an inquiry and our sales team will be glad to answer all your questions!

A breakthrough in monitoring of overhead power lines

The most part of the world electric transmission grid was built between the 1940s and 1980s in the times when fossil fuels dominated in energy demand and consumption, electric power system was developing simultaneously with it and at the same time the concepts such as renewable energy, high-speed internet and digitalization were in the infancy or even non-existent and seemed quite futuristic. In the last decade, the investments in renewable energy sources from distant windmill parks as well as massive digitalization have grown significantly. As a result, some parts of the transmission grid have become overloaded causing instabilities in the system.

To ensure the reliability of the power supply when the demand is growing, the current carrying capacity (ampacity) of some lines must be planned and gradually increased. One way of increasing the ampacity is to “reconductor” the overhead lines. Replacing the traditionally used ACSR (Aluminum Conductor Steel Reinforcement) conductors with High Temperature Low Sag (HTLS) conductors can increase the ampacity with no need to modify the existing towers and insulators. In this respect a new generation of conductor technology is introduced to the market.

Composite core technology

A composite core technology like ACCS (Aluminum Conductor Composite Single core) with composite core manufactured by De Angeli Prodotti (Italy) is one of those brand-new conductors. In the composite core conductor, the steel core is replaced by carbon-fiber strength member formed in the pultrusion process. Thus, there is no need for hard aluminum wires traditionally used in ACSR types of conductor anymore, because softer fully annealed aluminum with higher conductivity providing higher ampacity can be used instead. Compared to ACSR conductors, composite core conductor types have less weight, higher tensile strength and lower thermal expansion coefficient but can carry approximately double current. As a result, unnecessary investments in power towers can be avoided, as existing can be used for the grid upgrade.

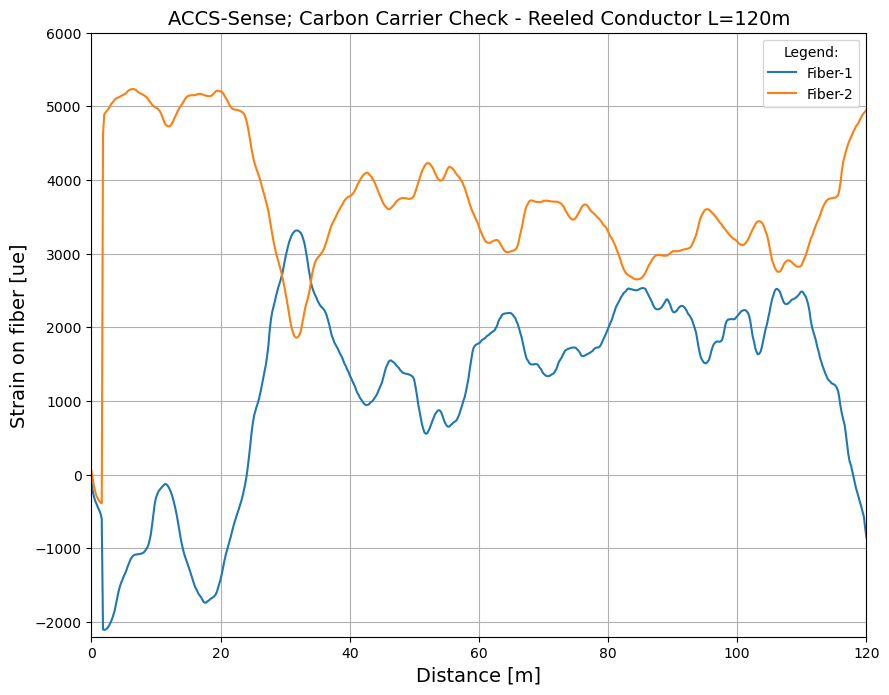

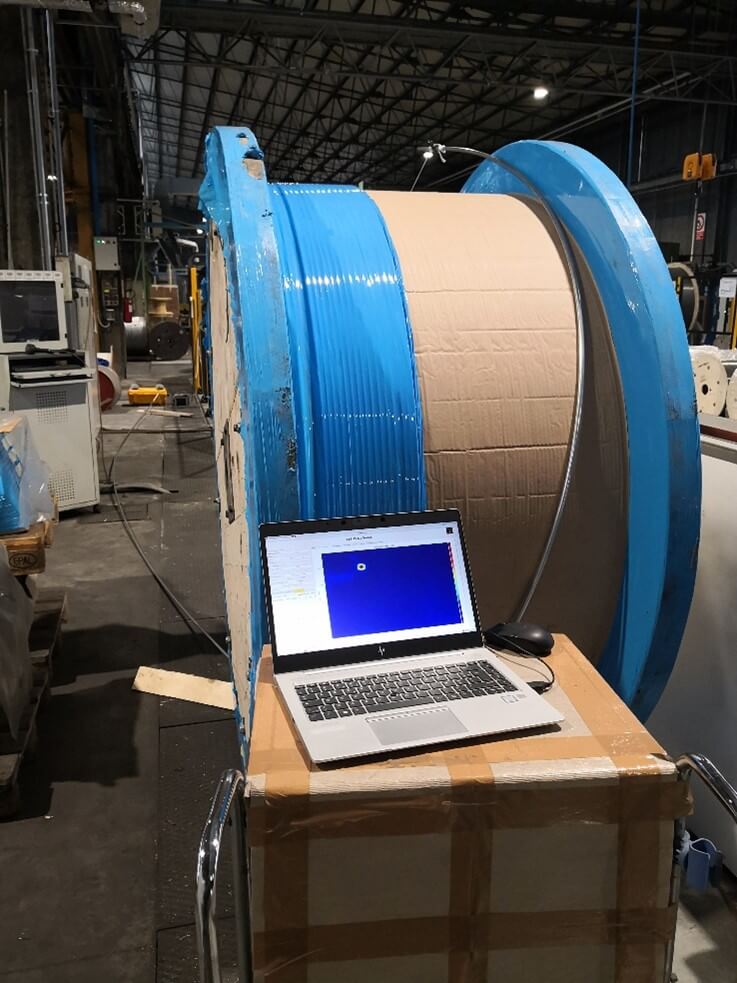

The deployment of composite core conductor technology is not straightforward as it requires satisfying certain technical standards and procedures in both production and installation, respectively. In collaboration with De Angeli Prodotti, a renowned manufacturer of carbon-fiber based powerline phase conductors, Wires&Bytes successfully introduced and deployed DFOS technology into a different application and industry – the power transmission, for the purposes of novel generation of HTLS conductors and their installation check and documentation. A special version of De Angeli’s ACCS conductor, now named and promoted as ACCS-Sens, integrating 3 specialty optical fibers is prototyped and manufactured at the production facility in Italy.

The installation of such conductor involves following the precise procedures that require real-time multi-fiber DFOS measurements. The concept exploits the idea of converting central carbon-fiber carrier into DFOS-ready mechanical beam making it suitable for strain, temperature, bending, vibration, and acoustic fully distributed measurements from the single end of the ACCS-Sens. After almost 2 years of R&D activities for the successful “fiber-sensitization” of conductor and adaptation of existing DFOS interrogation equipment, the technology is finally premiered on the installation site in Belgium in April 2021. The measurements revealed mechanical conditions which the conductor went through during its manufacturing and reeling processes continuing with the site delivery, installation, and stringing processes on the powerline. Moreover, presuming further innovation in the HV fitting technology, the application of these principles is feasible in the future during the operation as well. The acquisition of data from the conductor that is now provided can be beneficial to all in the supply and deployment chain: manufacturers, installers, operators, and grid owners. As the technology matures it might offer reaching longer distances thus introducing a novel type of powerline monitoring with competitive “per-km” costs. Along with further improvements and innovations it has potential to become a significant part of the data-driven smart grid plans across the globe.

13 Apr 2021

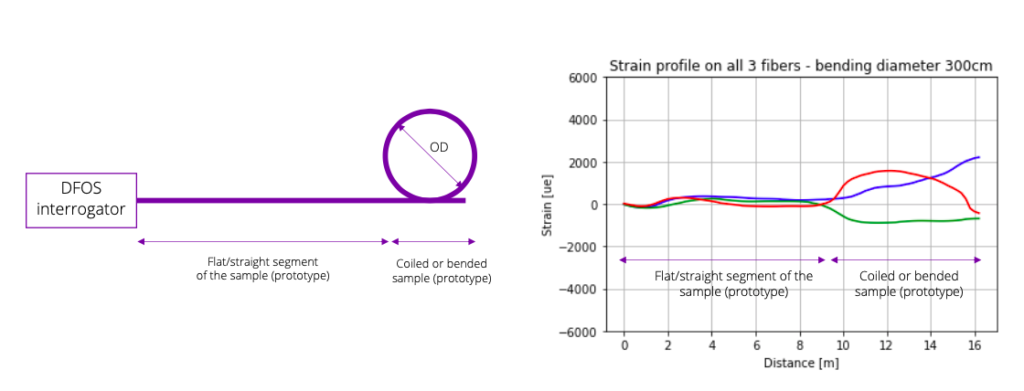

A deformation applied to an optical cable results in positive or negative longitudinal strain exerted along the circumference of the cable and this can be exploited for bend measurements using fiber optic cables. It is well-known in the industry that optical fibers are sensitive to longitudinal strain. A one-dimensional displacement — either expansion, or compression of the fiber — represents scalar strain, whereas three-dimensional displacement represents vectorial strain. The latter provides information on “bending” at that position. This is where a special class of fiber optic bend measurement cables can be deployed. The intelligent cable design using off-the-axis integration of multiple fibers inside the cable will provide full information on bending at that location.

Vector displacement information is extremely useful in various applications such as crack growth monitoring, umbilical, pipeline, tunnels, powerlines, and robotic arms. When a cable is embedded into the structure, it will take the shape of the structure allowing to explore the configuration. One of the demanding needs of the industry is to understand the dynamic movement of the structure using fiber optic sensing. Hence a cable that provides information on the cable bending along the entire length brings several benefits to the owners and operators, e.g., providing dynamic inclination information for the long structures and infrastructural objects helps the owners to predict the lifetime of their assets.

For fiber optic cables the cable bend measurement capability can be categorized in measurement ranges:

Measurement ranges determine possible interrogation techniques to be used. Long-range bend measurements capability has always been the focus for Wires&Bytes. The integration of these interesting features into new generation of fiber optic cables has resulted into a family of cables called MulitSense. Various MultiSense designs have been implemented in the field and their technical capabilities have been exceeding the customers’ requirements and expectations so far.

Taking into account the demanding applications, Wires&Bytes has developed a BendSense cable. Our new cable design is a further evolution of our MultiSense design to provide information on vectorial deformation from the cable. The new cable has multiple fibers, configured either twisted or non-coplanar inside the cable. This allows optical fibers to be sensitive to the bending regardless the bend plane and offering the end user to deduce bend direction and amplitude of the deformation.

All the cables have been thoroughly tested in our lab using BOTDR technology making sure Wires&Bytes delivers fit-to-purpose products. Wires&Bytes aims at helping you to develop and manufacture cables for specific bend measurements. You can be rest assured you are provided with the best technique to interrogate your cable, data acquisition, processing, and visualization, so you can get detailed insights of your assets’ integrity with our bend measurement cables.

Safe and reliable operation of any pipeline system requires applying new technologies to improve its inspection, operation, maintenance, and integrity management.

Wires&Bytes offers pipeline companies a holistic view toward preventing and detecting leaks and other damages using fiber optic technology. Pipeline integrity monitoring is one of those modern tools which ensures that pipelines do not cause harm to people or the environment, at the same time being reliable and secure source of information to pipeline operators.

Advantages:

👉 Visit the page to take a look at the video, where the process of pipeline integrity monitoring is shown and learn more

25 Mar 2021

Fatigue failure by flexing is a common failure mode for cables in a high flex environment. In order to predict it, there are various analysis tools and test procedures.

Keeping up with the latest developments, Wires&Bytes is presenting its newest addition to the Test Center — a reversing cable cycling machine, with programmable tension loads, suitable for precise bending tests. It fully complies with EN/IEC norms, but its technical possibilities exceed them!

This machine enables sophisticated lifecycle testing to customers’ exact specifications to ensure smoother and safer operations. It is now possible to cycle test and characterize for repeatable bending diverse cable types including electrical, fiber optic and mechanical slicklines and also wirelines of small sizes.

As part of Wires&Bytes extensive R&D offerings, we consider it a matter of the utmost importance to possess modern measurement and testing equipment. Thus, all our customers can be sure of top-notch quality of all our finished products.

We welcome your questions and requests to learn more about how we conduct our tests.

Make sure to address even the smallest details!