What a year 2022 has been, huh? We are reflecting and recollecting some moments of this year and anticipating 2023!

We wish you a Merry Christmas and a peaceful and prosperous New Year!

May this holiday season sparkle and shine, may all of your wishes and dreams come true, and may you feel this happiness all year round.

We look forward to working with you in the years to come!

Wires&Bytes team 💜

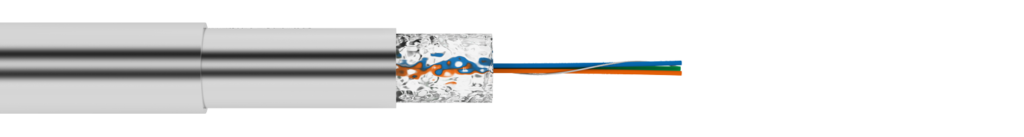

#1. SlickLight-C is a simple and cost-effective capillary-tube-based configuration for rapid telemetry and electrical power to downhole tools. But what is also great about it — is the armoring and stranding possibility for strength and advanced electrical return path features!

#2. Each SlickLight-C is available as an off-the-shelve product that can be designed and built in-house for YOUR customer-specific electrical, strength, and cost needs.

It’s fully customizable:

#3. SlickLight-C enables real-time communication of wireline tools of all types using slickline equipment. What does this mean to you? No more memory tools and waiting on your data! SlickLight-C is compatible with your Warrior system which you can continue to use with your electrical wirelines.

Do you want to know more? Contact us for details!

17 Nov 2022

Operating condition of an oil well must be monitored to avoid accidents and to have full control over the production processes in the well.

Oilfield services and geophysical operations are subject to detect, measure and classify vibroacoustic and temperature effects on producting tubings and along the well continuously. Traditionally, memory point sensors have been deployed for such tasks. In recent years, however, the use of optical fiber for distributed acoustic, temperature and today also static-strain sensing has proven effective.

Fiber optic cables and downhole tools can be used in the stages of planning of putting wells into operation, repair of existing wells and regular surveys of suspended wells.

Running cables to power the pump, collect information from point sensors and provide distributed fiber optic monitoring is a technical challenge, limited by the dynamics of the well and subsurface equipment.

Source: Unsplash

WB cables can be used for monitoring the well conditions cost-effectively and efficiently.

To solve this challenge, Wires&Bytes have developed a range of downhole cables that combine several functions at once:

Wires&Bytes offer both permanent and retrievable downhole cables for logging surveys and service operations for downhole installations:

Why use fiber optic sensor cables?

Wellbore fiber optic monitoring technologies using DAS, DTS and DSS measurement equipment turns cables into long-reach subsurface antennas helping to reduce survey time because distributed monitoring provides simultaneous temperature and acoustic measurements along the entire well, which is critical for studying the dynamics of rapidly evolving processes and changing events. WB hybrid cables allow different types of downhole tools to be connected to it and fiber optics for monitoring.

Contact us for details on how this technology can improve your production and how we can implement it in your location in a cost-effective way to get answers quick.

See you in Aberdeen next week at SPE ICoTA 28th European Well Intervention Conference!

Arrange a meeting with Saeed Rehman who will be there presenting Wires&Bytes products and solutions.

When: 16 — 17 November, 2022

Venue: P&J Live, Aberdeen, Scotland

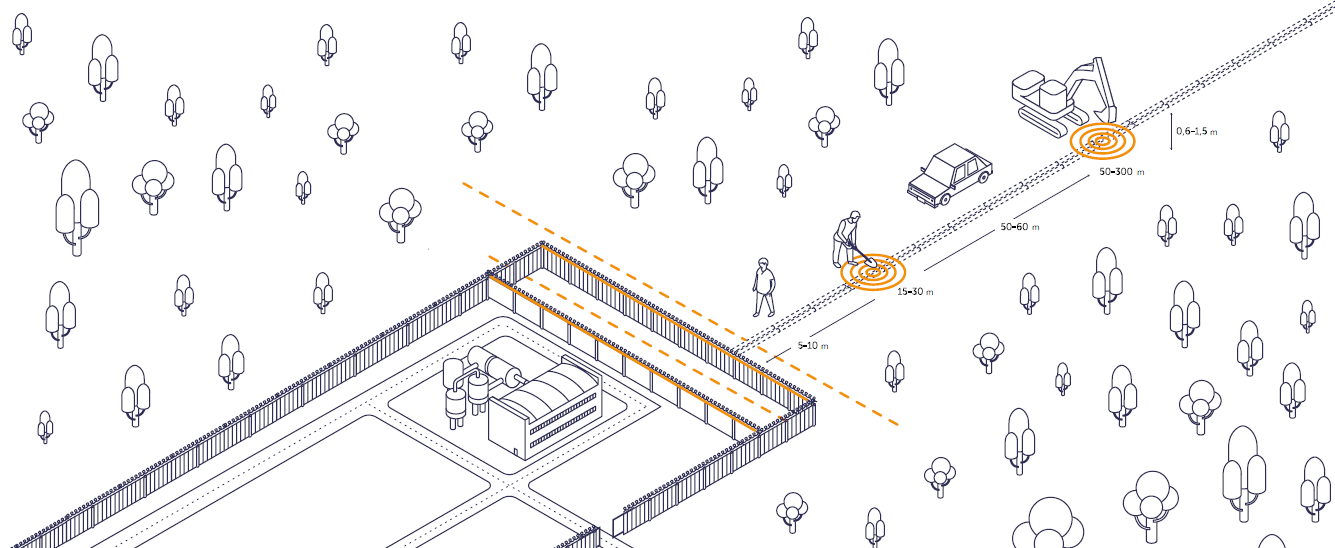

Perimeter security is one element of the overall security system used for protection of hazardous production, industrial and civil facilities. Generally, perimeter monitoring systems are installed at fuel and energy complex enterprises, nuclear power plants, military facilities, airports and other facilities with large areas. Please note, that any perimeter security system is only a part of the overall security system and in most cases additional visualization is needed. Therefore, perimeter security systems are often used together with video surveillance systems.

How can fiber optic technology help?

Fiber optic cable, not susceptible to electromagnetic interference, hidden and unseen by metal detectors in case of dielectric armor, is the basis of the control system. The principle of DAS (Distributed Acoustic Sensing) is based on the change in refractive index and elongation of the optical fiber section under the influence of vibroacoustic influences on it. In this case the cable can be attached to the fence or buried in the ground, providing early detection of an intruder at the border of the surveillance area. Often the optical cable is laid in several lines to determine the direction of intruders travel and reduce the number of false alarms.

Any mechanical impact on a fiber optic sensor cable changes the characteristics of the optical fiber inside it. These changes are analyzed and recorded, informing about the threatening event with the accurate location and class of impact. Moreover, it is a durable system with the proven design life of the main element, the optical cable, of 20 years.

Fiber optic system can detect:

— human steps 5-10 m from the cable,

— hand digging 15-30 m from the cable,

— moving car 50-60 m from the cable,

— heavy equipment digging 50-300 m from the cable.

What fiber optic cables out of the WB product line up can help you to monitor the perimeter?

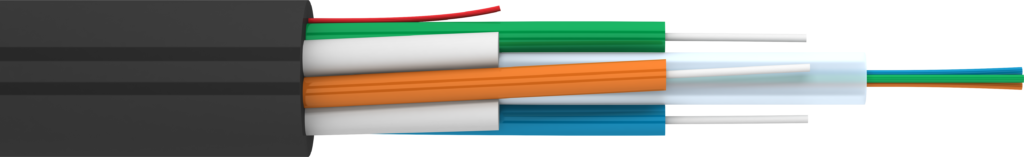

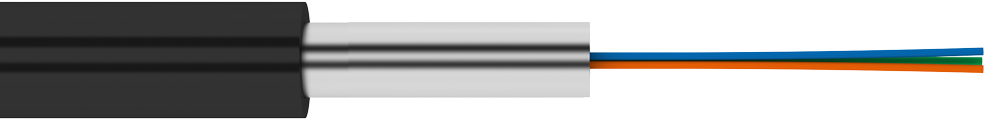

Multipurpose cable for monitoring of extended objects. The main feature of this cable is the ability to collect data on all types of distributed monitoring (DTS, DAS, DSS). It has an ultra-sensitivity to deformation and acoustic influences.

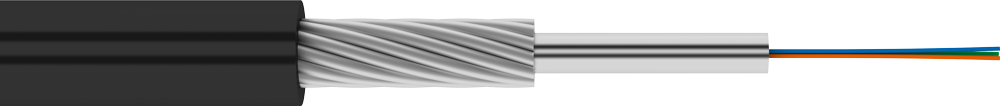

Lightweight universal cable for monitoring of extended objects on the basis of DTS and DAS

UniSense is an excellent solution for laying in different types of soils. The cable is robust against mechanical damage due to the armor of steel wires.

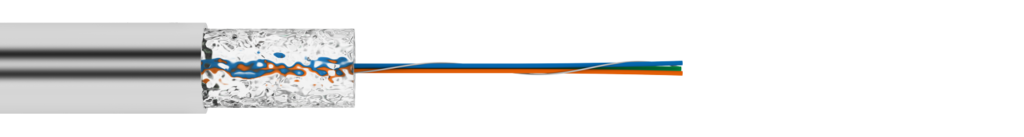

The FIMT cables can be used as part of urban infrastructure and laying along the industrial facilities, where the cross-section dimension of the sensor cable is critical while maintaining its resistance to tensile and crushing loads as well as high temperatures.

Come see us at ADIPEC! Find the samples of real Wires&Bytes products at the GOWell booth #3308,4110 (Hall 4) as well as grab the flyer about SlickLight-C.

If Wires&Bytes innovative electrical telemetry, power supply and fiber optic products and solutions seem interesting to you, please contact Saeed Rehman or Petar Basic to arrange a meeting for a detailed presentation!

When: 31 October — 3 November

Venue: Abu Dhabi National Exhibition Centre

𝘏𝘰𝘴𝘵𝘦𝘥 𝘣𝘺 𝘵𝘩𝘦 𝘈𝘣𝘶 𝘋𝘩𝘢𝘣𝘪 𝘕𝘢𝘵𝘪𝘰𝘯𝘢𝘭 𝘖𝘪𝘭 𝘊𝘰𝘮𝘱𝘢𝘯𝘺 (𝘈𝘋𝘕𝘖𝘊), 𝘈𝘋𝘐𝘗𝘌𝘊 𝘪𝘴 𝘵𝘩𝘦 𝘸𝘰𝘳𝘭𝘥’𝘴 𝘮𝘰𝘴𝘵 𝘪𝘯𝘧𝘭𝘶𝘦𝘯𝘵𝘪𝘢𝘭 𝘮𝘦𝘦𝘵𝘪𝘯𝘨 𝘱𝘭𝘢𝘤𝘦 𝘧𝘰𝘳 𝘰𝘪𝘭, 𝘨𝘢𝘴, 𝘢𝘯𝘥 𝘦𝘯𝘦𝘳𝘨𝘺 𝘤𝘰𝘮𝘱𝘢𝘯𝘪𝘦𝘴 𝘢𝘯𝘥 𝘱𝘳𝘰𝘧𝘦𝘴𝘴𝘪𝘰𝘯𝘢𝘭𝘴.

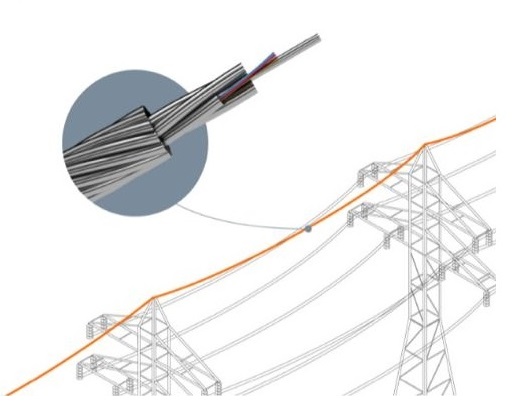

With the continuous development of fiber optics for telecommunications and measurement, overhead power lines are becoming the best example of the interplay between electric power transmission and long-distance light propagation. The gradual replacement of ground wires with optical ground wires (OPGW) over the years has made it clear that the two go hand in hand in long-distance power lines, providing high-speed communication and the modern Internet in every corner of the world.

It started with OPGW and telecommunications, but it doesn’t end there. Being dielectric in nature, optical fibers will offer more and more possibilities for overhead power lines, which are high-voltage environments with a high electric field. For example, thanks to the successful implementation of optical fibers in the ground wire, OPGW is becoming an element of power line monitoring systems, and in many different forms. Such systems can determine locations of increased environmental temperatures in the event of forest fires or lightning strikes on transmission lines, as well as short circuits and unauthorized activity in protected or hazardous high voltage areas, all with a spatial accuracy of just a few meters.

Application of modern fiber optic monitoring systems on the OPGW allows to:

Interested in this technology? Contact us for details!

Also take a moment to read our case study and watch our short educational videos:

⚡DFOS monitoring technology for overhead power HTLS conductors installation

⚡FOS technology integrated in OPGW

⚡Monitoring of suspicious activity near power lines using OPGW

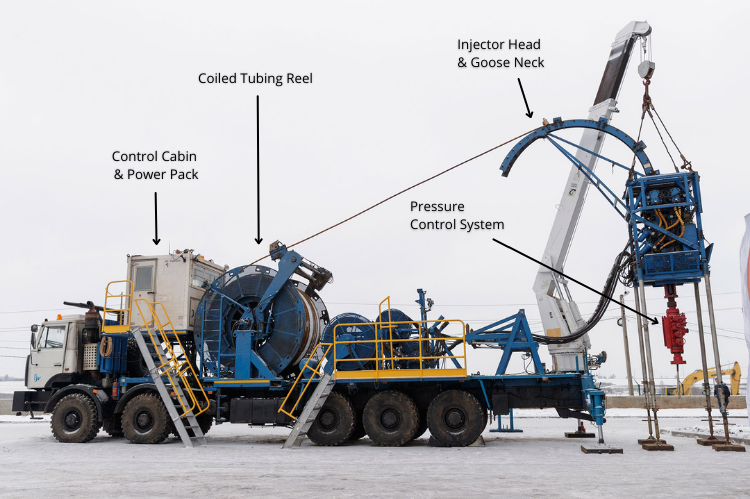

Coiled tubing, also called flexible tubing or CT, is a long continuous string of tubing spooled on a large reel. The technology was developed in the 1950-s but became widely used in the late 1980-s.

A coiled tubing unit (CTU) is used for development and refurbishment of oil and gas wells. The advantages of CTUs are that because of its shape the pipe can reach horizontal and side outflows without extra time spent on assembling/disassembling the tubing. This is what makes this technology cheaper and more eco-friendly than the traditional methods.

Field of application

CTUs are generally used for oil fields exploration, drilling and maintenance work. However, it is now being used for extraction of high-viscosity oil.

The technology is most widely used in the northern regions of Canada and the USA (Alaska).

Coiled tubing equipment

CTUs are used to transport and deploy the pipe of a necessary diameter into the well.

The equipment, mainly, installed on a self-propelled chassis or a semi-trailer.

The pipe size is adjusted to the type of operation. The usual diameter variation is within 19-114 mm. The pipe is spooled on the operating coil, which is installed on the truck frame. The pipe then goes through the injector head which creates a charge strong enough to push the pipe into the well considering friction force and pressure loss in the well hole.

Wires&Bytes fiber optic cables for coiled tubing

When coiled tubing is used for drilling and maintenance, it is necessary to deploy the equipment into a given part of the well and track its operational status. Wires&Bytes retrievable downhole cables are widely used for such purposes. Some cables can be manufactured as electrical, optical and hybrid.

At various stages of exploration of the oil field and during the maintenance of these wells, it is imperative to monitor the ongoing processes of the output well, in particular the temperature along the stem. Distributed temperature sensing (DTS) requires sensing cables with optical fiber as a distributed sensor. Wires&Bytes produces a line of sensing cables which are best suitable for such task. We use fiber resistant to extreme temperature to monitor temperature in CTU. The cable is located inside the pipe in the output well and is protected from harsh environment. We use 316 stainless steel and superalloys Incoloy 825 and Inconel 625 in our tube production. Armor wire is made of galvanized improved plowed steel or galvanized extra improved plowed steel or Ni-based alloys for higher corrosion resistance.

Please contact us for detailed information about designs suitable for Coiled Tubing application.

07 Sep 2022

How much the ground moves during an earthquake depends strongly on near-surface structure. And the shakings can be highly variable. Though the scientists have to admit, that the physics behind this variability is not entirely clear, partly because high-resolution instrumental observations are rare.

And here comes the fiber optic technology, particularly Distributed Acoustic Sensing which has a great potential for high-resolution seismic hazard mapping in urban areas.

On 4th July 2019 an M6.4 earthquake occurred near China Lake and Ridgecrest, California, followed by an M7.1 mainshock 34 hours later. Five days after the mainshock scientists used DAS enabled fiber optic cables (they basically repurposed an existing underground dark 10-kilometer fiber optic cables into seismic arrays) and performed high-resolution subsurface imaging which usually had been challenging. The Ridgecrest DAS array detected six times more aftershocks than the standard earthquake sensors within 3 months and allowed the team to build a model with sub-kilometer resolution 2 orders of magnitude higher than conventional models.

The model showed that along the length of the fiber, the areas where aftershocks caused more ground motion generally corresponded to those where shear velocity was lower.

As scientists say, seismic hazard and site amplification studies usually focus on ground motions (displacement, velocity, acceleration, etc.), while DAS measures the along-fiber strain field averaged over a finite gauge length.

The results of this research demonstrated that DAS-based noise tomography can capture subsurface structural heterogeneities. Such fine-scale seismic hazard mapping can improve urban seismic risk management, being both effective and inexpensive tool especially in urban areas where fiber optic networks are present already.

The use of DAS for seismic monitoring has very optimistic forecasts to play a fundamental role in the next generation seismic networks. The current tendency at local universities is to acquire DAS systems and use them with growing telecommunication network.

Wires&Bytes Non-Metallic MultiSense has already been deployed: it fits well to this application as it combines strain-coupled and strain-free fiber configuration. It has fibers with different strain sensitivities and it enables revealing more information on low frequency ground movement and acquisition of different types of seismic waves. Strain sensing fibers in the armor layer can be stranded to the customer specified helix lay-length, tuning the strain sensitivity of the cable and customizing it to a magnitude, exceeding the physical possibilities of uncabled optical fibers.

Interested in DAS enabled fiber optic cable technology? Contact us today and we will be able to present and offer you the best solution!

Source: Geophysical Research Letters, https://doi.org/10.1029/2021GL096503, 2022

It took a while for this to happen and the right prototype to be created, it may still take a few more months, perhaps years, to explore in detail what all this has to offer to the well intervention industry, but the most important thing is that it’s already here and it’s a good fit for a geothermal project!

New fully metallic multipurpose MultiSense is a DFOS cable for standard and elevated temperature ranges (180°C or 356°F) and has a size of a standard slickline of 4.60 mm (3/16 in).

It is designed to support different measurement configurations and scenarios and can be produced in several versions to fit application requirements.

For example, in a standard version it is a perfect solution for permanent installation attached to the production tubing or embedded into cement casing. In a version with a strength wire member (i.e. replacing one tube) added to internal stranding layer it can be used for well intervention just like a standard slickline. In another slightly different configuration it can be injected inside Coiled Tubing (CT).

All this is to exploit its main benefits – simultaneous and combined use of coupled fibers and loose fibers as an integrated means for acquisition of independent data. Since the design inherits all the benefits of metallic MultiSense initially designed for Structural Health Monitoring applications, and now being applied in a well intervention industry, different measurement principles are supported and can be combined and conducted together in a single slickline size of 4.60 mm. Good overview of different data types can contribute significantly to a better and easier event and data interpretation. These include Raman – DTS, DAS, BOTDA/R and Fiber Bragg Grating (FBG) types. Since all sensing elements are helically stranded inside the cable, the design is flexible enough to be spooled onto standard slickline or wirelines units. In general, the flexibility in design and production opens possibilities to support other customer-born proprietary measurement concepts that are yet to be proposed and realized.