A breakthrough in monitoring of overhead power lines

The most part of the world electric transmission grid was built between the 1940s and 1980s in the times when fossil fuels dominated in energy demand and consumption, electric power system was developing simultaneously with it and at the same time the concepts such as renewable energy, high-speed internet and digitalization were in the infancy or even non-existent and seemed quite futuristic. In the last decade, the investments in renewable energy sources from distant windmill parks as well as massive digitalization have grown significantly. As a result, some parts of the transmission grid have become overloaded causing instabilities in the system.

To ensure the reliability of the power supply when the demand is growing, the current carrying capacity (ampacity) of some lines must be planned and gradually increased. One way of increasing the ampacity is to “reconductor” the overhead lines. Replacing the traditionally used ACSR (Aluminum Conductor Steel Reinforcement) conductors with High Temperature Low Sag (HTLS) conductors can increase the ampacity with no need to modify the existing towers and insulators. In this respect a new generation of conductor technology is introduced to the market.

Composite core technology

A composite core technology like ACCS (Aluminum Conductor Composite Single core) with composite core manufactured by De Angeli Prodotti (Italy) is one of those brand-new conductors. In the composite core conductor, the steel core is replaced by carbon-fiber strength member formed in the pultrusion process. Thus, there is no need for hard aluminum wires traditionally used in ACSR types of conductor anymore, because softer fully annealed aluminum with higher conductivity providing higher ampacity can be used instead. Compared to ACSR conductors, composite core conductor types have less weight, higher tensile strength and lower thermal expansion coefficient but can carry approximately double current. As a result, unnecessary investments in power towers can be avoided, as existing can be used for the grid upgrade.

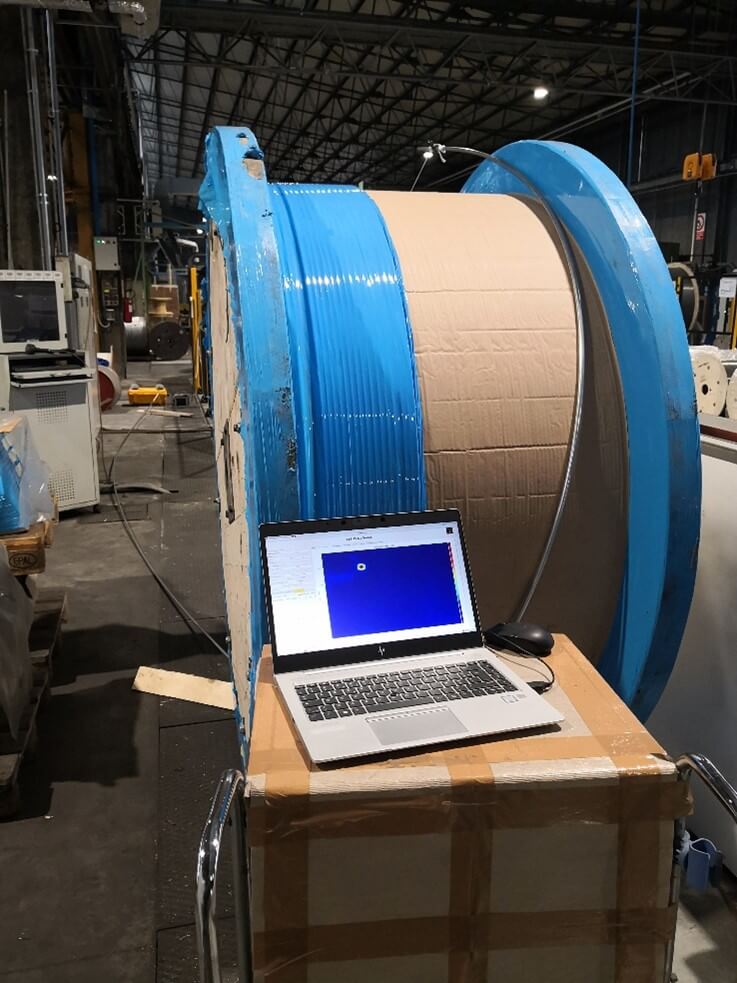

The deployment of composite core conductor technology is not straightforward as it requires satisfying certain technical standards and procedures in both production and installation, respectively. In collaboration with De Angeli Prodotti, a renowned manufacturer of carbon-fiber based powerline phase conductors, Wires&Bytes successfully introduced and deployed DFOS technology into a different application and industry – the power transmission, for the purposes of novel generation of HTLS conductors and their installation check and documentation. A special version of De Angeli’s ACCS conductor, now named and promoted as ACCS-Sens, integrating 3 specialty optical fibers is prototyped and manufactured at the production facility in Italy.

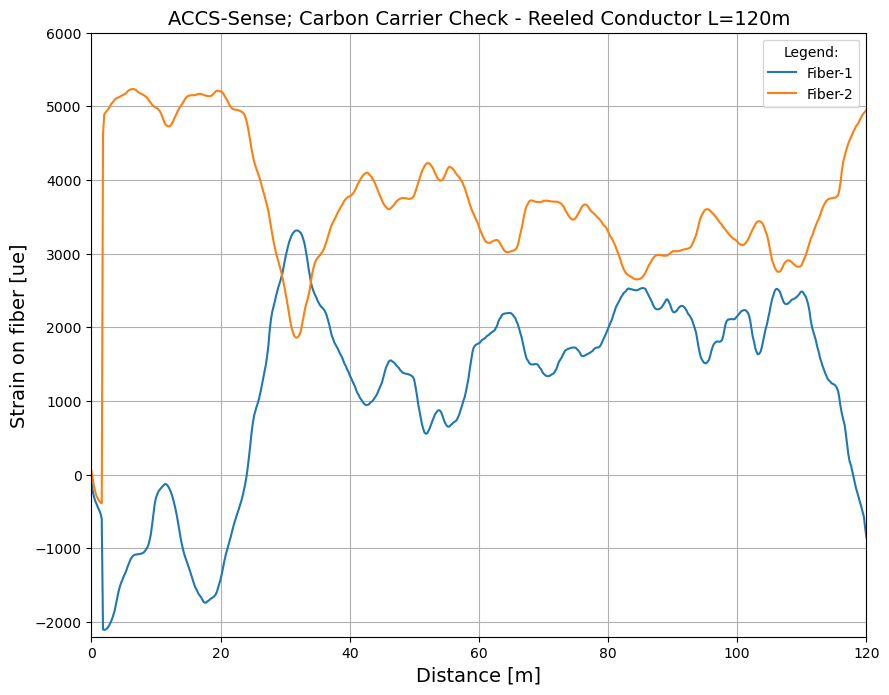

The installation of such conductor involves following the precise procedures that require real-time multi-fiber DFOS measurements. The concept exploits the idea of converting central carbon-fiber carrier into DFOS-ready mechanical beam making it suitable for strain, temperature, bending, vibration, and acoustic fully distributed measurements from the single end of the ACCS-Sens. After almost 2 years of R&D activities for the successful “fiber-sensitization” of conductor and adaptation of existing DFOS interrogation equipment, the technology is finally premiered on the installation site in Belgium in April 2021. The measurements revealed mechanical conditions which the conductor went through during its manufacturing and reeling processes continuing with the site delivery, installation, and stringing processes on the powerline. Moreover, presuming further innovation in the HV fitting technology, the application of these principles is feasible in the future during the operation as well. The acquisition of data from the conductor that is now provided can be beneficial to all in the supply and deployment chain: manufacturers, installers, operators, and grid owners. As the technology matures it might offer reaching longer distances thus introducing a novel type of powerline monitoring with competitive “per-km” costs. Along with further improvements and innovations it has potential to become a significant part of the data-driven smart grid plans across the globe.