11 Aug 2020

A comparative test has been performed to check the acoustic sensitivity of different types of Wires&Bytes cables for vibroacoustic influences at our test center. The cables, including UniTEF, OPGW, metallic and non-metallic MultiSense designs were tested at different acoustic frequencies and their responses were recorded and observed using Distributed Acoustic System. Results obtained in the test show differences in acoustic performance of the cables when tested under the same conditions.

Introduction

The objective of this study was to qualitatively test and determine acoustic performance of several cable designs, that are different in configuration and material used. The aim was to give users a better understanding of the acoustic performance of different designs, both standard and special, help them in selection of cables for different applications as well as set new goals for the development of new cable designs. For example, for a pipeline leak detection, where high frequency response is required for the deployed cables, positioned at some distance from the pipe, the right cable selection will ensure optimum monitoring. Another example would be selection of fully dielectric cables deployed along electrically powered railways, where the use of metallic designs raises significant safety issues limiting deployment in many countries around the world.

Test set-up

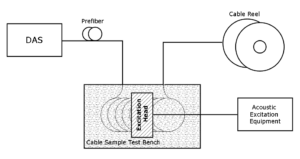

The test procedure involved building a specific cable-acoustics test bench (Fig. 1) and acquisition of different acoustical equipment including phase-sensitive DAS equipment.

Fig. 1: Acoustic Test Set Up for FO Cables

The cable sample is sandwiched between two soft material panels, acoustically excited from the top (Fig. 2) and interrogated with commercial DAS equipment. Laser pulse repetition rate used (LPRR) was 10 kHz with gauge length set to 16m.

Fig. 2: Cable Sample Test Bench for Acoustic Response Evaluation; (a) completed bench with loaded sample, (b) sample laying inside the bench, (c) mounting of excitation head

Fig. 3 Cables Samples tested

Only sinusoidal signals from both loudspeaker and subwoofer were used in the test. Acoustic signal frequencies recorded on each cable were: 40, 80, 160, 320, 640, 1280, 2560Hz – all multiples of 40 Hz to avoid possible interference with 50 Hz from the power supply network. Cables with the range dimensions, masses, configuration, and chemical compositions were sampled and used in the test.

Results

It is evident that cable characteristics such as mass, design, and fiber configuration and integration play an important role in acoustic response. Low frequency perturbation tends to have stronger impact than the higher frequencies.

To process signals at each of the frequencies, a narrow-band filter with a width of ± 5% of the signal frequency was used to eliminate ambient noise outside the studied frequency band (Fig. 4).

Fig. 4: Reconstructed signal value for different frequencies and cables

Conclusions

The results obtained in this test suggest that cable design can significantly contribute towards the performance of fiber optic sensing systems and their successful deployment and exploitation in the industry. The same level of response is expected when measuring strain. System designers need to take cable designs into consideration especially when a single cable should have mixed and multipurpose sensing features.