13 Apr 2021

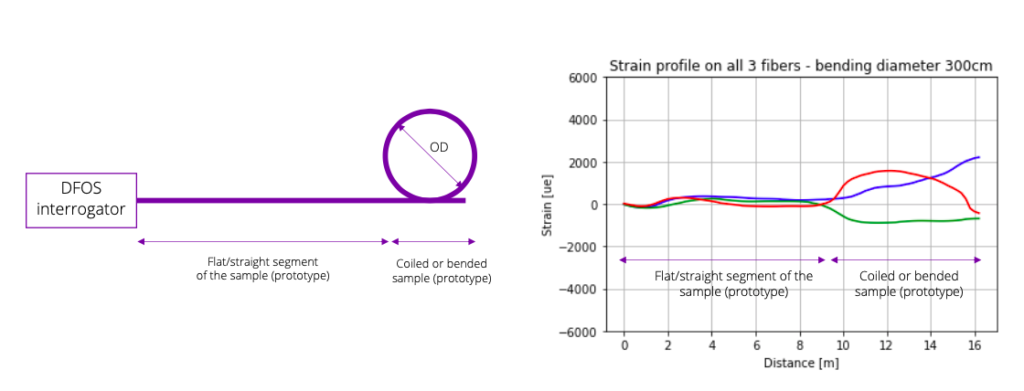

A deformation applied to an optical cable results in positive or negative longitudinal strain exerted along the circumference of the cable and this can be exploited for bend measurements using fiber optic cables. It is well-known in the industry that optical fibers are sensitive to longitudinal strain. A one-dimensional displacement — either expansion, or compression of the fiber — represents scalar strain, whereas three-dimensional displacement represents vectorial strain. The latter provides information on “bending” at that position. This is where a special class of fiber optic bend measurement cables can be deployed. The intelligent cable design using off-the-axis integration of multiple fibers inside the cable will provide full information on bending at that location.

Vector displacement information is extremely useful in various applications such as crack growth monitoring, umbilical, pipeline, tunnels, powerlines, and robotic arms. When a cable is embedded into the structure, it will take the shape of the structure allowing to explore the configuration. One of the demanding needs of the industry is to understand the dynamic movement of the structure using fiber optic sensing. Hence a cable that provides information on the cable bending along the entire length brings several benefits to the owners and operators, e.g., providing dynamic inclination information for the long structures and infrastructural objects helps the owners to predict the lifetime of their assets.

For fiber optic cables the cable bend measurement capability can be categorized in measurement ranges:

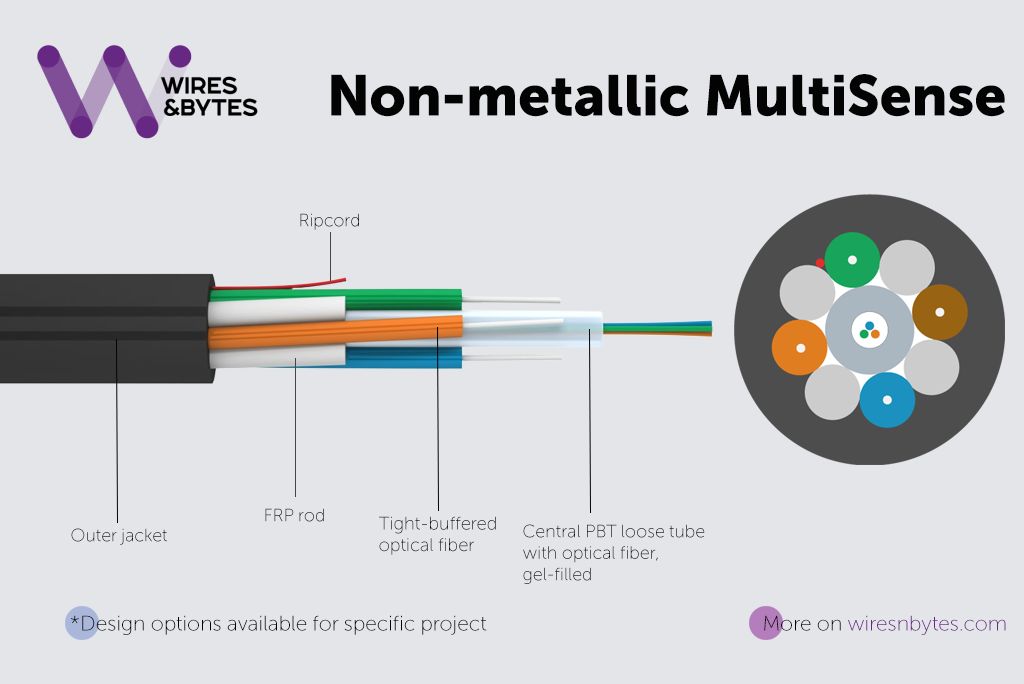

Measurement ranges determine possible interrogation techniques to be used. Long-range bend measurements capability has always been the focus for Wires&Bytes. The integration of these interesting features into new generation of fiber optic cables has resulted into a family of cables called MulitSense. Various MultiSense designs have been implemented in the field and their technical capabilities have been exceeding the customers’ requirements and expectations so far.

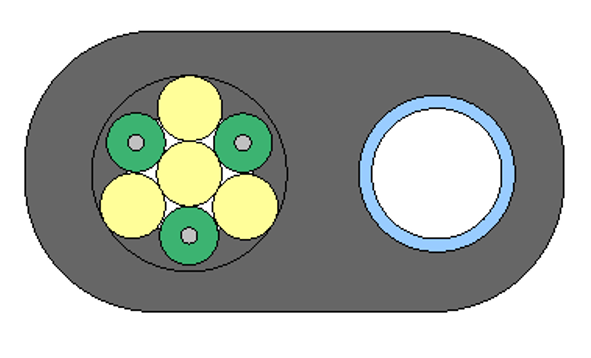

Taking into account the demanding applications, Wires&Bytes has developed a BendSense cable. Our new cable design is a further evolution of our MultiSense design to provide information on vectorial deformation from the cable. The new cable has multiple fibers, configured either twisted or non-coplanar inside the cable. This allows optical fibers to be sensitive to the bending regardless the bend plane and offering the end user to deduce bend direction and amplitude of the deformation.

All the cables have been thoroughly tested in our lab using BOTDR technology making sure Wires&Bytes delivers fit-to-purpose products. Wires&Bytes aims at helping you to develop and manufacture cables for specific bend measurements. You can be rest assured you are provided with the best technique to interrogate your cable, data acquisition, processing, and visualization, so you can get detailed insights of your assets’ integrity with our bend measurement cables.