In the world of oil, gas, and geothermal operations, every meter of wellbore presents a unique challenge. Extreme temperatures, high pressures, and corrosive fluids create an environment where conventional sensors and cables often fail. For operators, unreliable data isn’t just inconvenient — it can be costly or even dangerous.

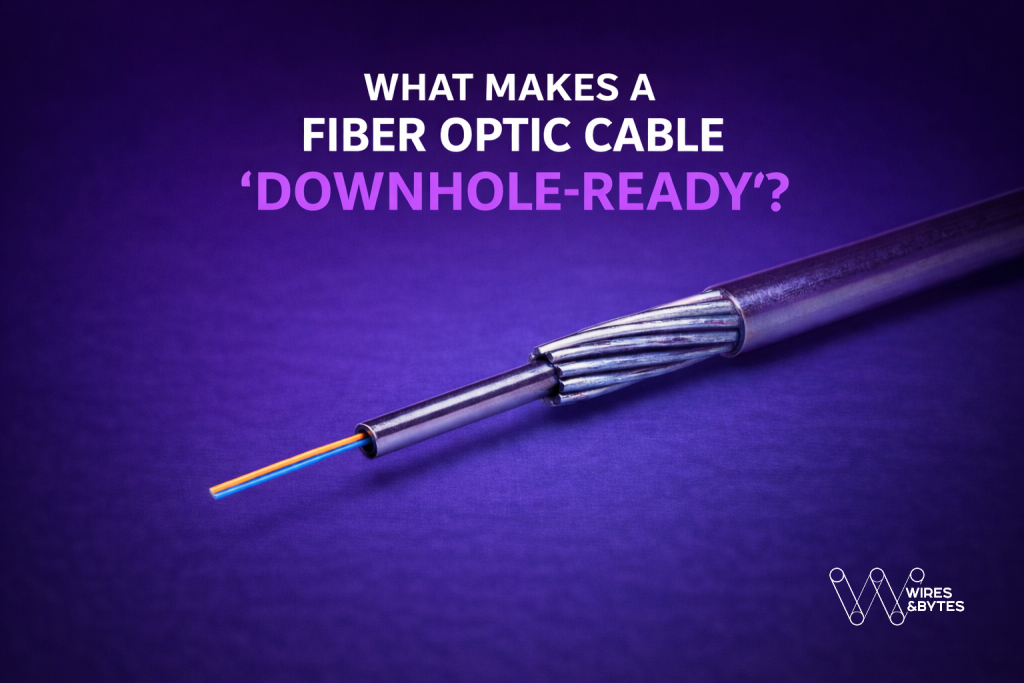

At Wires&Bytes, we design fiber optic cables that rise to this challenge. Our downhole cables are engineered to be high-temperature proof, ensuring reliable performance even in the harshest environments. But what exactly makes a fiber optic cable suitable for these extreme conditions?

A downhole fiber optic cable must withstand mechanical, thermal, and chemical stresses simultaneously. At Wires & Bytes, each cable combines advanced materials, careful layering, and precision engineering to meet these demands. Key design features include:

1. High-Temperature Proof Fiber Core

Our cables use single-mode fiber with hermetic coatings, such as carbon or polyimide, which maintain signal integrity even at elevated temperatures. This ensures that real-time data is never compromised, even in geothermal wells or high-temperature downhole operations.

2. Multi-Layer Protective Coatings

Buffer and secondary coatings shield the fiber from mechanical stress and chemical attack, preserving long-term reliability.

3. Strength Members for Deployment Resilience

Armored steel wires provide tensile strength during installation and operation, protecting the fiber against stretching or damage.

4. Robust Outer Jacket and Armor

Chemical- and abrasion-resistant materials such as polyurethane, PFA, or stainless steel armor protect the cable from external damage, ensuring longevity even in the most aggressive well environments.

These high-performance cables are at the heart of modern sensing solutions, including:

Distributed Temperature Sensing (DTS)

Distributed Acoustic Sensing (DAS)

Distributed Strain Sensing (DSS)

By delivering continuous, high-resolution data, operators can detect anomalies early, optimize production, and improve overall well safety.

Investing in high-temperature proof fiber optic cables is more than a technical decision — it’s a strategic one:

Enhances operational safety by providing early warnings of potential issues

Reduces downtime and intervention costs

Enables smarter, data-driven decisions in real time

At Wires& Bytes, reliability is not just a feature; it’s a responsibility. Every cable is engineered to ensure operators get the insights they need, whenever and wherever they need them.