Wires and Bytes is pleased to announce its latest cable designs for upgrading a Coiled tubing unit to an electric coil (e-coil). W&B state-of-the-art Fiber-based or Copper conductor-based cables empower companies with a newfound versatility in their service offerings, revolutionizing the capabilities of coiled tubing operations.

𝐓𝐡𝐞 𝐤𝐞𝐲 𝐚𝐝𝐯𝐚𝐧𝐭𝐚𝐠𝐞𝐬 𝐨𝐟 𝐮𝐩𝐠𝐫𝐚𝐝𝐢𝐧𝐠 𝐭𝐨 𝐞-𝐜𝐨𝐢𝐥 𝐢𝐧𝐜𝐥𝐮𝐝𝐞:

⚙️ 𝘝𝘦𝘳𝘴𝘢𝘵𝘪𝘭𝘦 𝘛𝘰𝘰𝘭 𝘊𝘰𝘯𝘷𝘦𝘺𝘢𝘯𝘤𝘦:

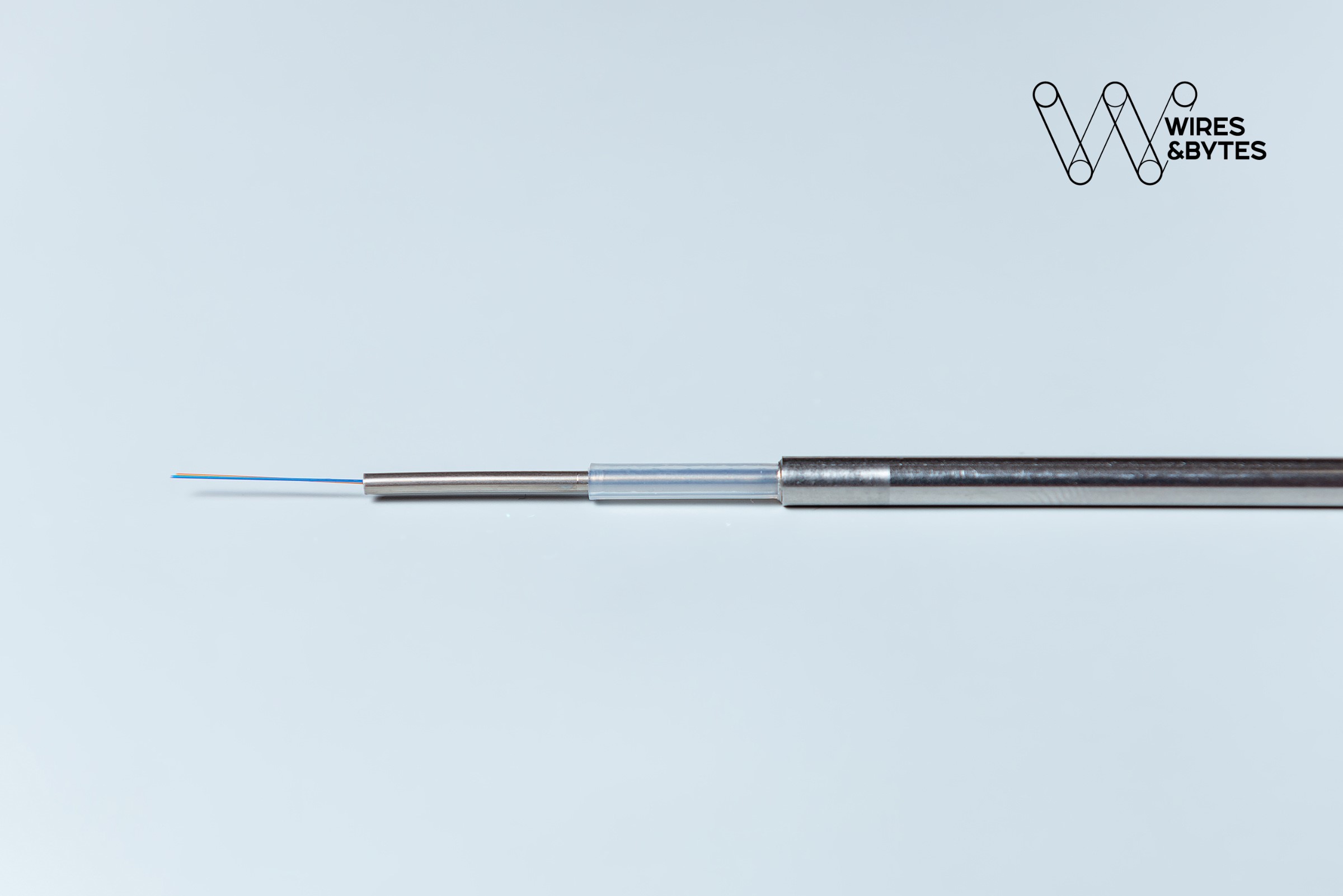

Coiled tubing enabled with digital, or fiber optic cable ensures the transmission and reception of power and communications to and from downhole equipment. This breakthrough feature allows the deployment of an extensive array of smart tools on coiled tubing, ranging from logging tools and perforating assemblies to cameras and Measurement While Drilling (MWD) assemblies.

⚙️ 𝘛𝘢𝘪𝘭𝘰𝘳𝘦𝘥 𝘌𝘲𝘶𝘪𝘱𝘮𝘦𝘯𝘵 𝘚𝘦𝘭𝘦𝘤𝘵𝘪𝘰𝘯:

When selecting equipment for the coiled tubing unit, careful consideration is paramount. Factors such as the number of conductors in the cable or required fiber count, maximum voltage and current specifications, zoning requirements, maximum pressure and temperature thresholds, and the cable injection mechanism must be considered to ensure optimal performance.

⚙️ 𝘊𝘳𝘪𝘵𝘪𝘤𝘢𝘭 𝘊𝘰𝘮𝘱𝘰𝘯𝘦𝘯𝘵𝘴 𝘧𝘰𝘳 𝘙𝘦𝘭𝘪𝘢𝘣𝘪𝘭𝘪𝘵𝘺:

A robust rope socket and conductor or fiber optic termination at both ends of the e-line are of utmost importance. These components, coupled with the implementation of correct slack management procedures, play a pivotal role in preventing downtime due to e-line failure and in maximizing the cable’s lifespan.

Wires and Bytes provides cutting-edge solutions that empower businesses to elevate their operations. This upgrade to e-coil technology not only enhances the efficiency of coiled tubing units but also opens doors to a wider range of applications and services.

Contact us for inquiries and further information on the benefits of upgrading to e-coil. wires.