A couple of months ago we published an article about an innovative and multifunctional cable SlickLight.

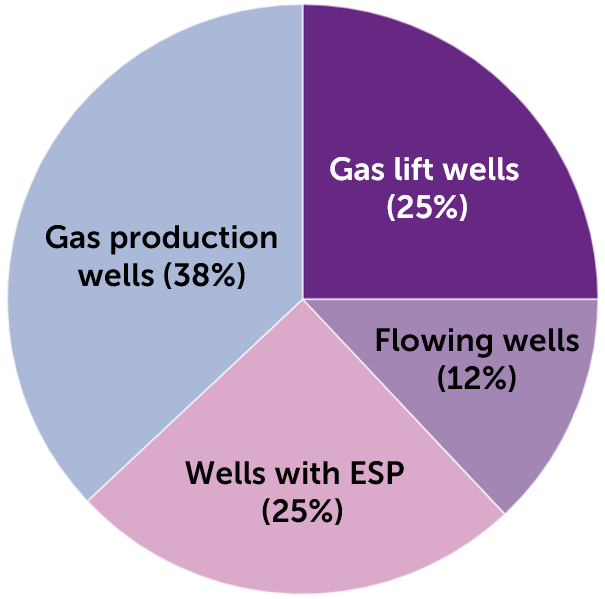

Recently, we conducted a survey to gather opinions on where this cable is best used. The results of this survey are in the chart below to provide insight when deciding where to apply SlickLight.

There are no wrong or right answers, instead, we wanted to focus on the key benefits and receive feedback based on your experience in well intervention. Among the answers were flowing wells, gas production wells, gas lift wells and wells with ESP.

Gas production wells got most of the votes, followed by gas lift wells and wells with ESP. Because of its simplicity and related efficiency, SlickLight technology is also very convenient for many gas and gas lift wells. For the gas wells this is because of the benefits of having small footprint and perfectly roundness of the cable with corrosion resistant metal jacket. For the gas lift wells other benefits add to it – firstly, access to the entire length of the well is not being hindered by the pump as with other artificial lift techniques. Also, in many cases, the amount of equipment, personnel and operation involved is reduced compared to other well-logging techniques.

Even though flowing wells got the least number of votes, however it is also very effective and beneficial to use SlickLight technology for this application.

SlickLight is an efficient way to take measurements in flowing wells without shutting them down or disrupting wells operations. Simplified sealing technique at wellhead and cable integrated pressure migration barrier make it one of the most effective options for the flowing and gas wells.