Fiber optic technology for measuring physical parameters currently is one of the fastest growing areas of applied optics. Fiber optic sensors compared to classical sensors have unique advantages, such as high sensitivity, immunity to electromagnetic interference, small size, light weight, robustness, flexibility, and the ability to provide multiplexed or distributed sensing. Due to these unique properties, they are widely used in solving various scientific and practical challenges, in which it is necessary to measure temperature, deformations and other parameters of extended objects.

Fiber optic sensors can be divided into two groups:

— point sensors

— and distributed sensors.

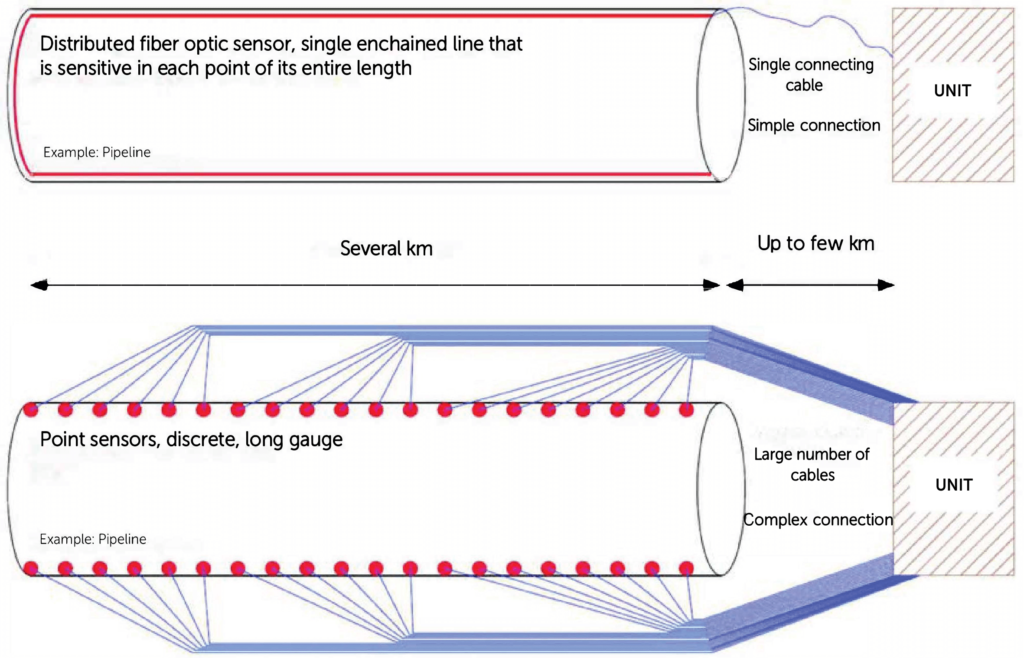

Optical fibers are the core in both concepts, still they significantly differ technically and commercially. Because of this both address applications in different ways.

From the technical point of view point sensors type is based on the use of a fiber Bragg grating (BBR) as a transducer of the measured effect into an optical signal. Since the size of standard fiber optic cables is small (not more than a centimeter), point sensors measure temperature values or strain only at the single point where the cable touches the surface. To get measures at several points it is necessary to form a monitoring system. The number of point sensors in a single fiber line can be ~100 and considering the possible light loss a sensor system with a large number of point sensors can be considered as quasi-distributed.

In contrast to point sensors, distributed fiber optic sensors, in industry known today as DFOS, use the entire length of the optical fiber as the sensing medium. Scattered light (due to Rayleigh, Mandelstam-Brillouin, or Raman effects) is used as the measured optical signal, and Optical Time Domain Reflectometry (OTDR) method allows measuring the distribution of temperature, strain, acoustics, or other external influence along the entire optical fiber length. Measuring systems based on scattering can be inferior to distributed systems based on a large number of point sensors in spatial resolution and sensitivity but have such an important advantage as the spatial continuity of the measured parameter.

Given the differences in technical aspects, it can be said that both technologies are priced differently from a commercial point of view. To be competitive in most cases they must be cost-optimized, proving their costs per measurement point or cost per unit length. When measurements involve long distances and many measurement points, DFOS systems have no significant competition among other technologies. Unique cost-per-kilometer or cost-per-number-of-measurement-points features of a DFOS system providing informative colorful spatial profiles, some in the real time, over the entire length of the sensor cable proved to be the largest commercial advantage. Within the scope of DFOS possibilities the investor decisions are easy-to-make, whereas for a point-based system which is much more versatile in terms of measurements and measurands, decisions must be considered on a more case-by-case basis. Developments in recent years show that point sensors have found their deployment niche in the applications where the combination of size, sensitivity and measurement accuracy matters most. As technology improves and new products enter the market, we can expect more innovative approaches, both technical and commercial.

In recent years, fiber optic sensors have demonstrated considerable potential for physical measurements and other practical applications. This is largely due to their sensitivity to a wide range of physical quantities, chemical stability, durability, ease of interfacing to high-speed and noise-proof fiber optic communication lines, fire and explosion safety. Safety is especially important for applications associated with combustible and explosive materials, such as coal, oil and gas production, etc. In addition, fiber optic sensors are quite compact, do not require systematic maintenance and are very resistant to chemical attack.

In coal, oil and gas production fiber optic sensors are used primarily for measuring temperature (usually by Raman method) and pressure (interferometers) in wells, as well as for pipeline monitoring. Fiber temperature sensors can also be used in fire alarm systems of various structures, as well as in the energy industry (monitoring heating elements of turbine generators, power lines, transformers, etc.). Deformation and vibration sensors are also used in power engineering (for example, to prevent the destruction of turbine generators). Radiation-resistant sensors are used in the nuclear power industry. Deformation and vibration sensors are used for structural health monitoring (bridges, tunnels, dams, dams, offshore oil platforms, foundations, roofs, high-rise buildings, etc.). Recent studies and experiments demonstrated that fiber optic sensors can even be implemented in composite materials for monitoring purposes in aircraft construction, space technology, etc.

If we compare the costs required to deploy both systems (point sensors and distributed sensors), the cost of distributed fiber optic sensing is much lower, because it does not require additional costs for powering the sensor element. In addition, for deployment of an accurate monitoring system a large number of point sensors would be needed (depending on the length of the object), so the cost of the point sensors cumulatively would be much higher than the cost of the fiber optic cable.

Taking everything into account, fiber optic sensors can be considered as the most promising approach to monitoring purposes for many industries, and Wires&Bytes team can assist you if you are investigating how DFOS technology can be of any help to your project. Let us know!