26 May 2021

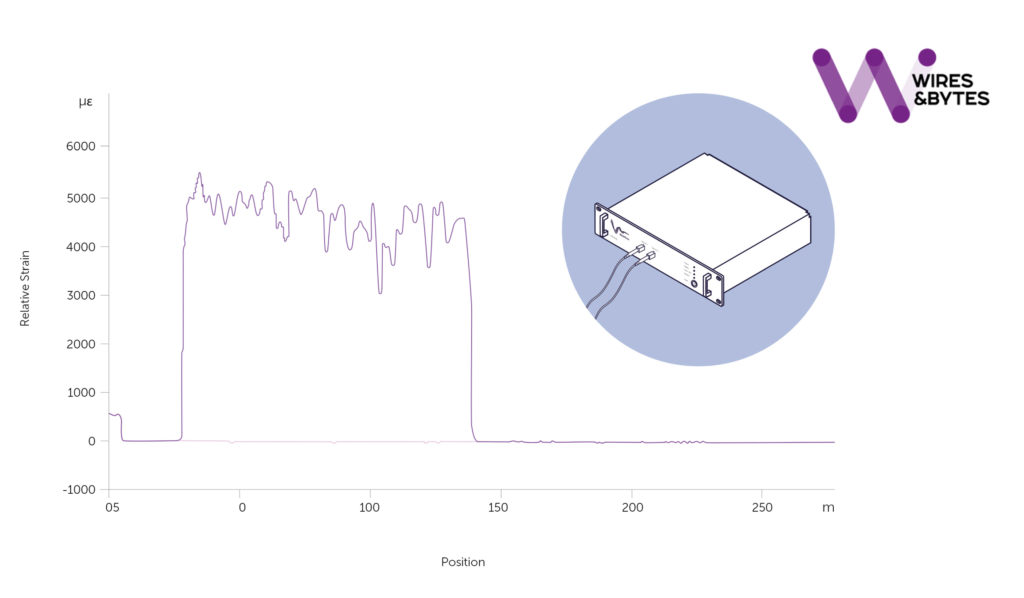

Mechanical properties play a critical role in defining fiber optic cable reliability and life expectation. One of the key measurands which dictate mechanical reliability is the residual strain in the final cable after it is manufactured. Wires&Bytes measures distributed strain at the in-house Test Centre to study residual strain in their cables before shipping to the end customer. This is an extremely valuable measurement tool that can help to understand the cable mechanics in depth, for example, predicting the lifetime of optical fiber and fiber optic cables in applications.

At Wires&Bytes cables are tested with a Brillouin analyzer which enables measuring the distribution of mechanical stress and fiber elongation along the entire length by the following techniques:

What we measure:

How you benefit:

The experience and data gained from the Brillouin analyzer help us in advising customers how to deploy cables in the most efficient way and with the best installation methods.

Need more details on that? Send us an inquiry and our sales team will be glad to answer all your questions!