Coiled tubing, also called flexible tubing or CT, is a long continuous string of tubing spooled on a large reel. The technology was developed in the 1950-s but became widely used in the late 1980-s.

A coiled tubing unit (CTU) is used for development and refurbishment of oil and gas wells. The advantages of CTUs are that because of its shape the pipe can reach horizontal and side outflows without extra time spent on assembling/disassembling the tubing. This is what makes this technology cheaper and more eco-friendly than the traditional methods.

Field of application

CTUs are generally used for oil fields exploration, drilling and maintenance work. However, it is now being used for extraction of high-viscosity oil.

The technology is most widely used in the northern regions of Canada and the USA (Alaska).

Coiled tubing equipment

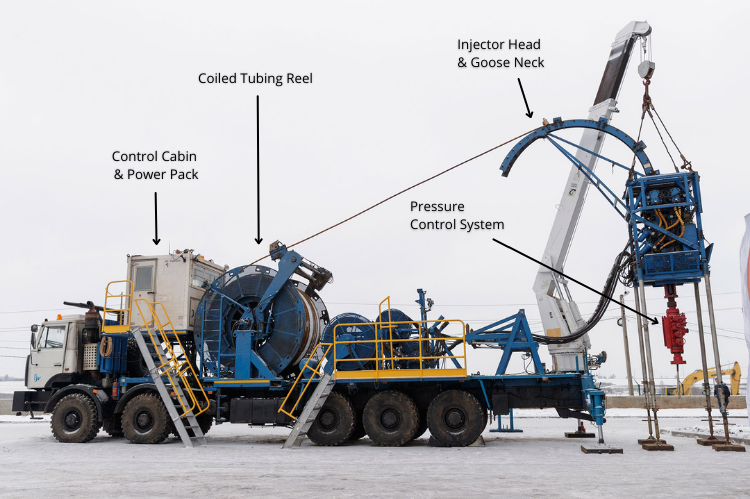

CTUs are used to transport and deploy the pipe of a necessary diameter into the well.

The equipment, mainly, installed on a self-propelled chassis or a semi-trailer.

The pipe size is adjusted to the type of operation. The usual diameter variation is within 19-114 mm. The pipe is spooled on the operating coil, which is installed on the truck frame. The pipe then goes through the injector head which creates a charge strong enough to push the pipe into the well considering friction force and pressure loss in the well hole.

Wires&Bytes fiber optic cables for coiled tubing

When coiled tubing is used for drilling and maintenance, it is necessary to deploy the equipment into a given part of the well and track its operational status. Wires&Bytes retrievable downhole cables are widely used for such purposes. Some cables can be manufactured as electrical, optical and hybrid.

At various stages of exploration of the oil field and during the maintenance of these wells, it is imperative to monitor the ongoing processes of the output well, in particular the temperature along the stem. Distributed temperature sensing (DTS) requires sensing cables with optical fiber as a distributed sensor. Wires&Bytes produces a line of sensing cables which are best suitable for such task. We use fiber resistant to extreme temperature to monitor temperature in CTU. The cable is located inside the pipe in the output well and is protected from harsh environment. We use 316 stainless steel and superalloys Incoloy 825 and Inconel 625 in our tube production. Armor wire is made of galvanized improved plowed steel or galvanized extra improved plowed steel or Ni-based alloys for higher corrosion resistance.

Please contact us for detailed information about designs suitable for Coiled Tubing application.