We hope you are fully immersed in the joyful holiday season, getting your work completed, wrapping presents, organizing festivities, and settling in by the fireplace to enjoy your favourite Christmas films.

It’s a perfect moment to reflect on another incredible year!

As we look back, we would like to recap our accomplishments and share some highlights from our journey with you!

❄️

Expanding our reach

This year, our cables reached 9 countries worldwide, including Germany, France, Italy, UK, Saudi Arabia, UAE, Oman, US, and Canada. And considering our

commitment to sustainability, all our packaging is designed with the environment in mind – using either recyclable wooden drums or reusable steel drums.

❄️

Welcoming new partners

A

new partner from Kuwait has joined Wires&Bytes family, opening up exciting possibilities for future collaborations and expanding our global presence.

❄️

Showcasing at exhibitions

Wires&Bytes proudly participated in 6 major exhibitions across the globe, connecting with industry leaders and showcasing our innovative solutions. We thank you for your interest to our product in all the events from International Petroleum Technology Conference in Saudi Arabia, Offshore Technology Conference in the US and Asia, Indonesia International Geothermal Convention & Exhibition, and all the way to ADIPEC in UAE and Oil&Gas Annual Conference and Expo in India!

Special attention should be given to our featured articles in ADIPEC magazines, which highlight our innovative smart cables that drive decarbonisation and digitalisation efforts:

DECARBONISATION GUIDE (page 166)

DIGITALISATION GUIDE (page 152)

❄️

Significant projects that make an impact

Among the remarkable projects we undertook this year, three stand out:

Our recent accomplishments include a tailored solution developed for an Oil and Gas company involved in the

Carbon Capture Storage initiative. This innovative technology shows great potential in addressing climate change, and we are excited to contribute to the advancement towards a more sustainable future.

Another important milestone is a project in Austria, aimed at producing sustainable energy from the earth’s depths to provide Vienna’s district heating. The first geothermal plant is scheduled to be commissioned in 2028, with additional plants to follow. We strongly believe that

geothermal energy is a game-changer for sustainable power and we are thrilled to be part of the project!

Furthermore, our high-performance cable designed specifically for offshore platforms has garnered renewed interest. Following positive feedback on its quality and efficacy, our client in Norway has placed another order for this durable and customized product.

❄️

Launch of production facility in the Middle East

We’re happy to have our first visitors at our

new production facility in Abu Dhabi which will strengthen our presence as a local manufacturer in the Middle East, adding in country value production (IKTVA or ICV) for our customers.

❄️

Gratitude and Warm Wishes

And we did it all with you! Thank you for another amazing year together!

Source of the image: unsplash.com

Source of the image: unsplash.com

❄️ Gratitude and Warm Wishes

And we did it all with you! Thank you for another amazing year together!

❄️ Gratitude and Warm Wishes

And we did it all with you! Thank you for another amazing year together!

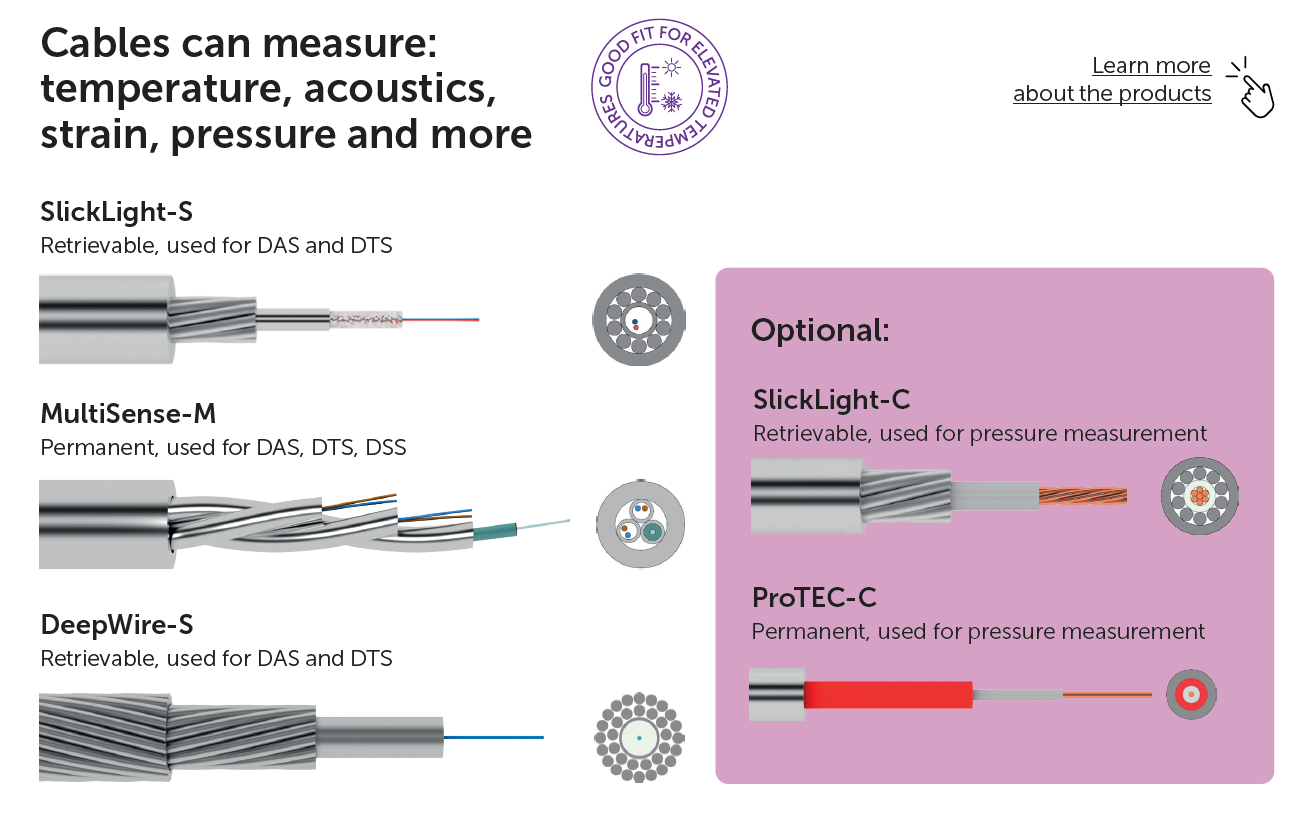

Download the leaflet

Download the leaflet