We strive to develop market-driven and fit-for-purpose cables for the O&G industry. With innovation and shared dedication, we integrate advanced features in our cables, we aim to enhance our customer capability for intelligent surveillance and the ability to make decisions on site.

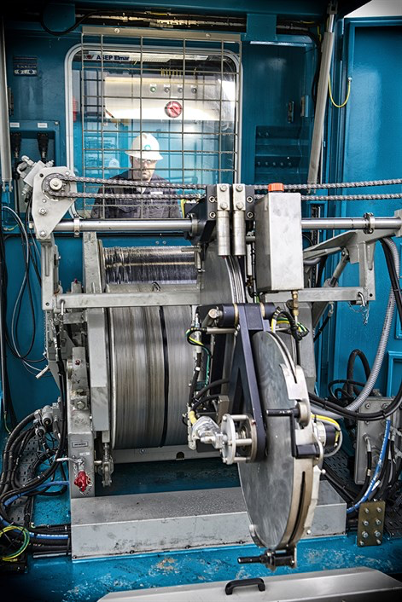

Recently, our fiber optic slickline with steel encapsulation has been deployed for a downhole well trial in Europe. The fiber-enabled slickline was successfully tested on the wellsite, providing DAS/DTS data as well as rapid visualization, manipulation, and integration of DFOS information with other well data.

The customer used their existing crew winch and pressure control equipment minimizing the need for additional crew and hardware. The DFOS data from the slickline can now be fully integrated with other customer’s services, enabling them to offer a comprehensive surveillance package to operators.

Our engineers meticulously test these slicklines for mechanical and optical standards, making sure they meet stringent requirements for the downhole harsh environment. These slicklines are also available in hybrid version, making it easy for customers to obtain optical test data along with running their electrical PLT tools.

Please contact us for details about the technology, how it can enhance your production and how we can support you in implementing it in the most cost-effective way.

➡️ Explore our slickline technology to learn more.

Our industry tends to think of slickline as a low tier option to make largely mechanical changes to the well later in its life. With the development and continuous improvement of memory tools there has been an ever-increasing role of slickline to deploy memory tools and later retrieve the information for analysis and interpretation.

We believe we are on the verge of a significant change in the way slickline is used and perceived. The evolution of slickline started with the first fiber optic slickline (~2010) when a Distributed Temperature survey (DTS) was deployed from a slickline drum into wells to measure flow profiles and do gas lift optimization. That huge step turned the entire line into an instrument which measured temperature along the full wellbore in real time. We saw that the performance of the reservoir was not static and gas lift valves chattered, opened and closed and rarely functioned exactly as designed.

Fast forward to today where Distributed Temperature Surveys (DTS), Distributed Acoustic Surveys (DAS) and an electrical signal can all be built into a single 4.8 mm (0.189 inch) or smaller line.

The possibilities are endless:

— Depth correlation via traditional gamma ray collar locator tools

— Flow profiles using DTS and DAS to give quantitative flow from perfs in non-horizontal wells

— Injection profiles from warm back data

— Leak detection using DAS and DTS

— Gas lift monitoring of the entire system at the same time – no station stops at a moment in time

— DAS to monitor for microseismic events from a nearby frac well to get frac height

— DAS to monitor strain and microseismic from an offset well for frac growth and prorogation

This new slickline technology combined with easy-to-use software and acquisition units will change the slickline industry to one where complex well analysis can be done in real time from the wellsite. Gas lift wells are run at the optimum production rate, frac analysis and modeling can be verified and improved for the local geological impacts.

Contact us for details on how this technology can improve your production and how we can implement it in your location in a cost-effective way to get answers quick.

Over 360 km of Wireline design WireCompoJack have been deployed and successfully operating at oil fields of one of Oil & Gas operators in Russia.

The cable provides connection of the surface interface unit with downhole measuring systems, lowered into the well.

Downhole measuring systems provide real-time monitoring of reservoir pressure and temperature at the pump intake. Thanks to this, the well operation modes are optimized.

All W&B cables pass the necessary qualification tests before delivery and show high operational reliability. Successful experience in the development and implementation of this type of cables allowed expansion of the Wireline family designs for Oil & Gas industry.

Wires&Bytes introduces downhole slickline cables for the Oil & Gas industry

All Oil & Gas operators need access to data for reservoir management. Common applications are well integrity, well performance and well optimization. Leaks in the system can cause environmental expenses, inefficient artificial lift systems and costly unplanned workovers. These are difficult to detect and locate using conventional single point measurements.

The advent of Distributed Fiber Optic Sensing (DFOS) measurements allows operators to monitor the entire well length in real time for the duration of the survey which makes DFOS uniquely suited to detect hard-to-locate well integrity problems and to efficiently optimize gas lift systems. A key enabler to make real time DFOS measurements is a reliable fiber optic slickline. Together with the appropriate surface interrogation units, effective data processing and visualization software a fiber program can improve profitability.

A number of service providers are addressing fiber deployment issues specifically lowering the base cost which today limits the use of fiber optic technology. Advanced service providers are utilizing new low cost slickline deployment techniques which leverage existing infrastructure and require very little in the way of additional skills for technicians.

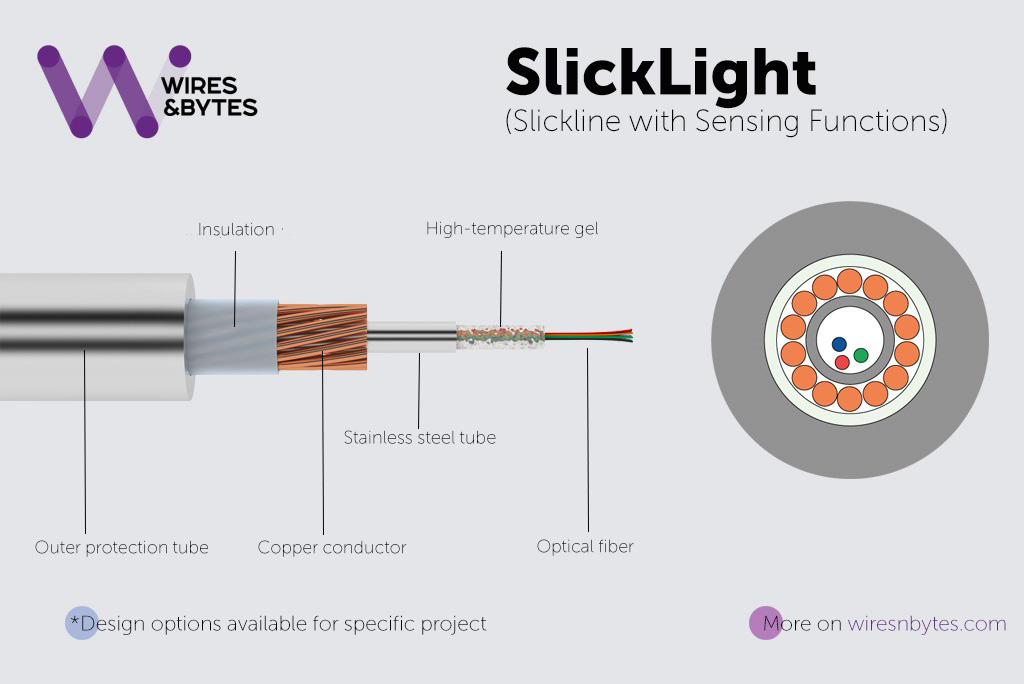

Wires&Bytes introduces a range of downhole hybrid slickline cables for application in coil tubing and well logging. These robust and retrievable cables, which can be exposed to the downhole environment including H2S and high temperature, are made of highly corrosion-resistant stainless steel wires. These cables are designed to have high breaking strength and can be used to perform for years of service.

SlickLight cable designs are available in the following configurations:

This all-optical design comes with a range of fiber options, size, weight and rated breaking strength up to 7900 N. These cables are marketed with max deployment length of 5.0 km (16.400 ft).

This heavy duty SlickLight cable is targeted for long and deviated wells with max rated breaking strength of 15800 N and max deployment length of 8.3 km (27.200 ft).

A hybrid version, which incorporates both optical fiber and copper. The optical fiber is used for DFOS measurement while copper is used for power and communication for electronic tools and tractors. Max rated breaking strength is 8200 N and max deployment length is 4.7 km (15.400 ft).

Important! Mechanical performance of fiber can be measured in our fully equipped lab according to your specifications or requirements.

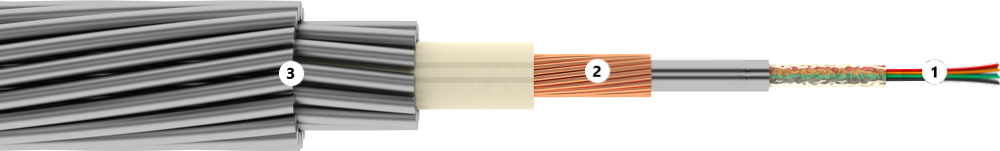

Wires&Bytes presents a new design for wireline cabling. This cable was designed for oil and gas industry, in particular for logging into downhole for purpose of well intervention, reservoir evaluation, and pipe recovery.

Benefits of design:

1. Thanks to optical fiber, forming a part of new SensoWire, this design is used for industrial distributed sensing DTS/DAS.

2. Copper conductor incorporated in this design can provide power to equipment located at the end of the cable.

3. Double layer of stainless steel wires allows to lower equipment or measurement devices.

Discover more here

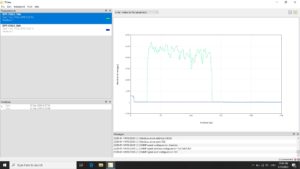

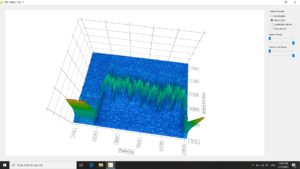

Wires&Bytes test center introduced a new state-of-the-art measuring device: Brillouin analyzer based on Brillouin Optical Frequency Domain Analysis (BOFDA).

Unlike equipment measuring changes in signal phase and providing only averaged values of fiber elongation, with this device using Brillouin scattering it is possible to measure the distribution of mechanical stress and fiber elongation along the entire length.

With the help of this device, you get precise and complete information on the characteristics of specific delivery lengths of specialty cables used for distributed structural health monitoring.

This allows setting up the control system, which is faster and more efficient, ensuring predictable cable response to external events that need to be monitored.

Our clients from telecom sectors can be sure in high quality of cables, which means not only high characteristics of optical fiber, but also their reliability. BOFDA measurements ensure absence of critical fiber stresses inside the cable along the entire delivery length and under any external influences (tension, bending, torsion, high and low temperatures).