Civil infrastructures all over the world often make use of underground development being a perfect choice when it comes to crossing mountain ranges, connecting islands to continents, managing urban and extra-urban roads, rail and road traffic, running large hydroelectric power plants, etc.

Europe and the US have an extensive in-service tunnelling heritage. Many of these tunnels have been in operation for decades already and are therefore prone to deterioration and degradation, though they are still key elements in community life. Their decommissioning might have a strong impact on the economy, logistics, sustainable development (especially in “green” terms) and social activity.

Thus, maintaining existing tunnels and proper construction of new underground infrastructures are crucial. And here come structural health monitoring systems that can be installed in tunnels, providing status information, and helping to manage maintenance.

Fiber optic sensors is a key part in DAS, DSS, DTS and other fully distributed systems. DFOS allows monitoring of deformations and temperatures along the whole length of a tunnel offering unique features: measures of physical parameters (acoustic, temperature, strain, etc.) can be done of thousands of points from a single read-out unit. The sensing cable is not sensitive to electromagnetic disturbances, withstands hostile environments and does not require power supply. The whole length of the sensing cable can reach up to 30 km though tunnel disturbance events such as concrete cracks, deformations, water ingress, fire, and others can be localized quite accurate at the point of damage.

The monitoring system allows a fully automatic and continuous monitoring of the tunnel integrity, and rapid alerts can be generated based on predefined criteria. DFOS provides timely data that help maintain tunnels effectively before any major damage and increase the safety of the structure.

Wires&Bytes MultiSense cable can be a perfect choice for SHM of in-service tunnels. Despite its small size and low weight, it supports all types of DFOS and deliver multiple measurements.

The design combines 4 tight buffer stranded fibers in a stranding layer and 3 or 4 fibers in a central loose tube. Stranded fibers are in a tight physical connection to the outer plastic jacket, ensuring quality transfer of measurands to the optical fibers such as for DAS and DSS measurements.

Since 4 fibers are provided, a careful combination of

can provide information on distributed curvature and bending of the cable, as well as compensation of ripples in the Brillouin measurements resulting in profiling plain longitudinal strain measurement apart from other induces stresses.

Loose fibers in the central tube can be both single-mode and multimode type and can be used for building different measurement configurations, such as loops for more precise stimulated Brillouin measurement, or distributed temperature measurements for temperature compensation purposes. Its configuration, multifiber design and versatility were the reasons for MultiSense to be selected and used in several structural health monitoring projects including tunnel monitoring in Italy and France. Once deployed in the structure with secured access to both ends, the cable leaves it up to the operator and the expert to decide how it will be interrogated.

Get in touch today and we will be able to advise, supply, install and support your optimal solution!

FIMT is a robust tube made of corrosion-resistant steel with optical fibers inside. It can be used as a component to produce robust cables for distributed sensing and data transmission. Its simplicity (including its manufacturing process) and strength make it a perfect choice for Oil&Gas industry and structural health monitoring applications.

Main applications of FIMT:

FIMT can be used at temperatures up to +300°C and higher (for cable in the polymer jacket up to +260°C). Double-layer tube design significantly improves mechanical performance, especially resistance to crushing loads.

👉Learn more about FIMT

👉Fill out a questionnaire and describe your project requirements

Or send us a request and we’ll offer the best solution!

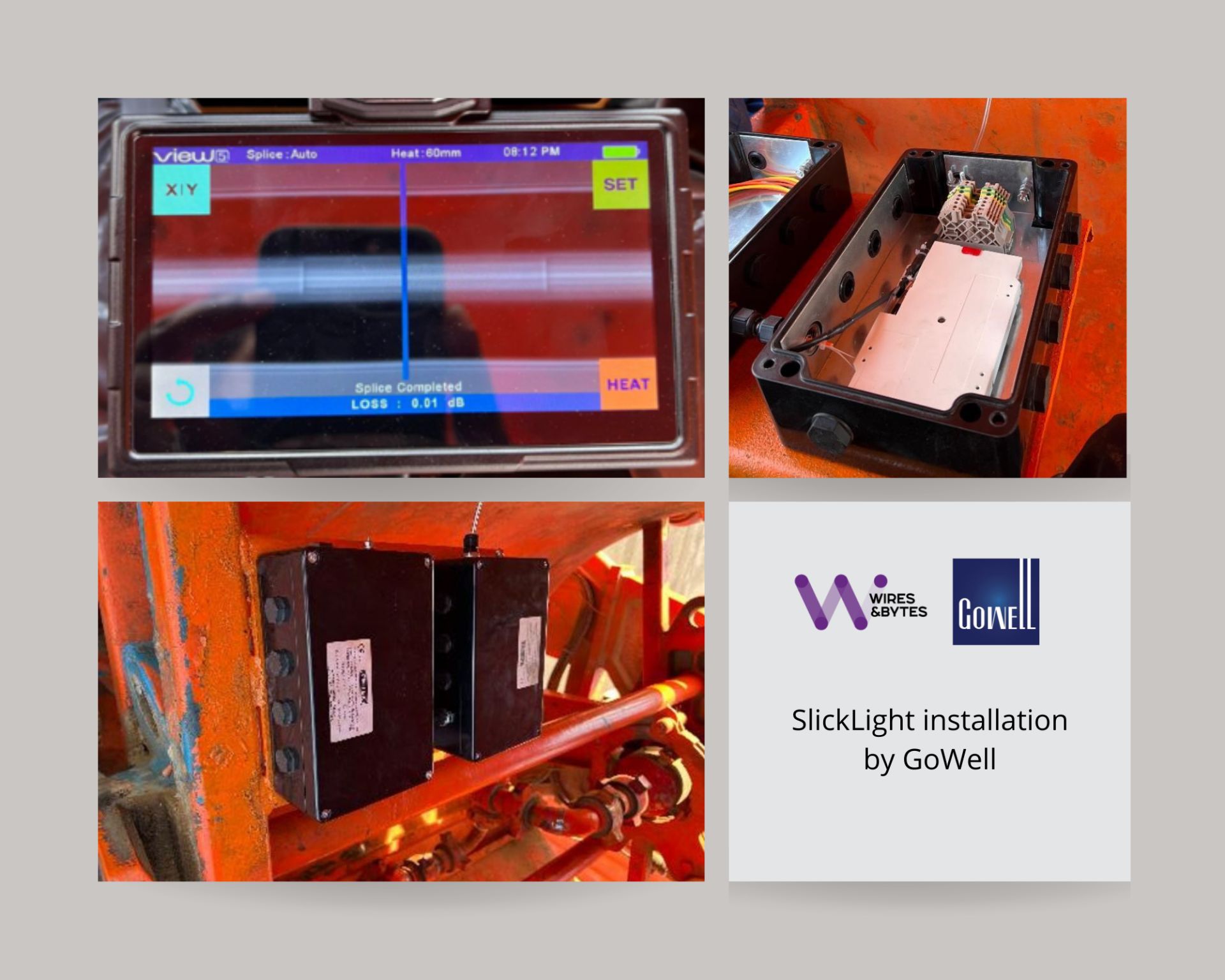

A client in the Middle East has successfully deployed a multipurpose electro-optical SlickLight cable which was installed inside Coiled Tubing and has now been used for multiple jobs that combine distributed temperature and acoustic measurements (DTS/DAS) with SRO e-line PL logging tools from a major WL service provider.

GOWell as our partner in the Middle East provided on-site support to prepare and ready the cable installation for data acquisition.

Looking for the best optical cable suitable for your project but don’t have time to explore the website and technical details? Then fill out our questionnaires directly on the Wires&Bytes website. We’ll review your request and get back to you with the best cable design offers ASAP.

The steps are simple:

Alternatively, here are the direct links to different questionnaires:

Petar Bašić, VP Technology at Wires&Bytes:

— SlickLights are DFOS slicklines that are retrievable downhole fiber optic cables designed to be used with common traditional slickline winches and equipment. When talking about design life, all the DFOS SlickLights (S and H types in particular) manufactured by Wires&Bytes are type tested for at least 100 well runs, collecting over 100TByte high value data during the lifetime. What really matters is efficiency in the triangle: acquisition of sufficient amount of data, low-cost operation and spending less time in the fields. If used properly, some designs can exceed 1000 well runs. For most efficient deployment of SlickLights please contact Wires&Bytes experts. They will take into consideration all important details of your wellbore data acquisition project and offer the best solution!

Fiber optic technology for measuring physical parameters currently is one of the fastest growing areas of applied optics. Fiber optic sensors compared to classical sensors have unique advantages, such as high sensitivity, immunity to electromagnetic interference, small size, light weight, robustness, flexibility, and the ability to provide multiplexed or distributed sensing. Due to these unique properties, they are widely used in solving various scientific and practical challenges, in which it is necessary to measure temperature, deformations and other parameters of extended objects.

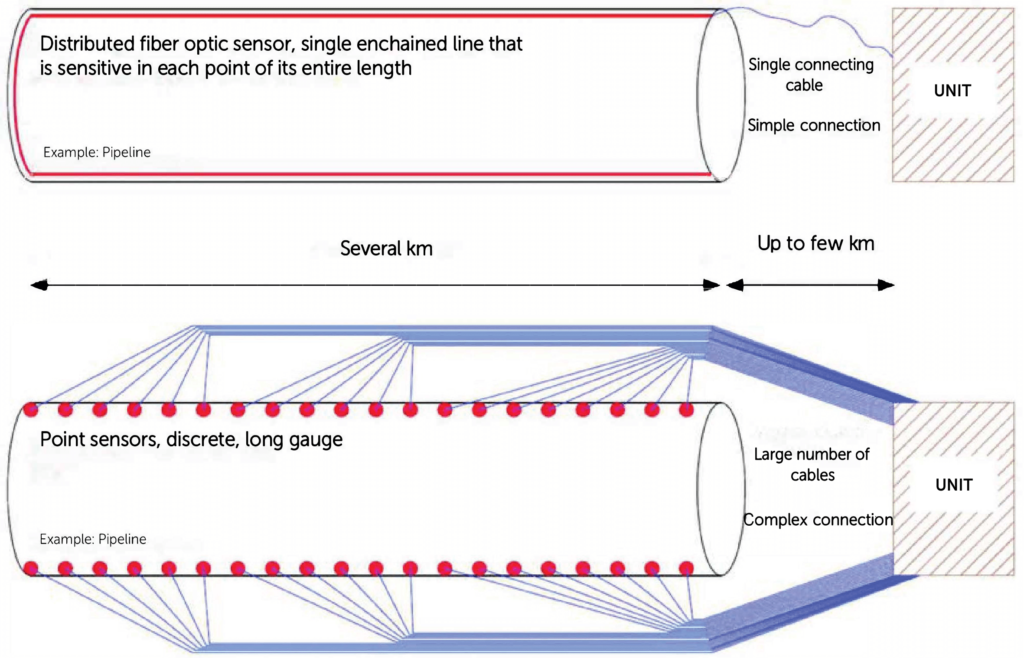

Fiber optic sensors can be divided into two groups:

— point sensors

— and distributed sensors.

Optical fibers are the core in both concepts, still they significantly differ technically and commercially. Because of this both address applications in different ways.

From the technical point of view point sensors type is based on the use of a fiber Bragg grating (BBR) as a transducer of the measured effect into an optical signal. Since the size of standard fiber optic cables is small (not more than a centimeter), point sensors measure temperature values or strain only at the single point where the cable touches the surface. To get measures at several points it is necessary to form a monitoring system. The number of point sensors in a single fiber line can be ~100 and considering the possible light loss a sensor system with a large number of point sensors can be considered as quasi-distributed.

In contrast to point sensors, distributed fiber optic sensors, in industry known today as DFOS, use the entire length of the optical fiber as the sensing medium. Scattered light (due to Rayleigh, Mandelstam-Brillouin, or Raman effects) is used as the measured optical signal, and Optical Time Domain Reflectometry (OTDR) method allows measuring the distribution of temperature, strain, acoustics, or other external influence along the entire optical fiber length. Measuring systems based on scattering can be inferior to distributed systems based on a large number of point sensors in spatial resolution and sensitivity but have such an important advantage as the spatial continuity of the measured parameter.

Given the differences in technical aspects, it can be said that both technologies are priced differently from a commercial point of view. To be competitive in most cases they must be cost-optimized, proving their costs per measurement point or cost per unit length. When measurements involve long distances and many measurement points, DFOS systems have no significant competition among other technologies. Unique cost-per-kilometer or cost-per-number-of-measurement-points features of a DFOS system providing informative colorful spatial profiles, some in the real time, over the entire length of the sensor cable proved to be the largest commercial advantage. Within the scope of DFOS possibilities the investor decisions are easy-to-make, whereas for a point-based system which is much more versatile in terms of measurements and measurands, decisions must be considered on a more case-by-case basis. Developments in recent years show that point sensors have found their deployment niche in the applications where the combination of size, sensitivity and measurement accuracy matters most. As technology improves and new products enter the market, we can expect more innovative approaches, both technical and commercial.

In recent years, fiber optic sensors have demonstrated considerable potential for physical measurements and other practical applications. This is largely due to their sensitivity to a wide range of physical quantities, chemical stability, durability, ease of interfacing to high-speed and noise-proof fiber optic communication lines, fire and explosion safety. Safety is especially important for applications associated with combustible and explosive materials, such as coal, oil and gas production, etc. In addition, fiber optic sensors are quite compact, do not require systematic maintenance and are very resistant to chemical attack.

In coal, oil and gas production fiber optic sensors are used primarily for measuring temperature (usually by Raman method) and pressure (interferometers) in wells, as well as for pipeline monitoring. Fiber temperature sensors can also be used in fire alarm systems of various structures, as well as in the energy industry (monitoring heating elements of turbine generators, power lines, transformers, etc.). Deformation and vibration sensors are also used in power engineering (for example, to prevent the destruction of turbine generators). Radiation-resistant sensors are used in the nuclear power industry. Deformation and vibration sensors are used for structural health monitoring (bridges, tunnels, dams, dams, offshore oil platforms, foundations, roofs, high-rise buildings, etc.). Recent studies and experiments demonstrated that fiber optic sensors can even be implemented in composite materials for monitoring purposes in aircraft construction, space technology, etc.

If we compare the costs required to deploy both systems (point sensors and distributed sensors), the cost of distributed fiber optic sensing is much lower, because it does not require additional costs for powering the sensor element. In addition, for deployment of an accurate monitoring system a large number of point sensors would be needed (depending on the length of the object), so the cost of the point sensors cumulatively would be much higher than the cost of the fiber optic cable.

Taking everything into account, fiber optic sensors can be considered as the most promising approach to monitoring purposes for many industries, and Wires&Bytes team can assist you if you are investigating how DFOS technology can be of any help to your project. Let us know!

Not long-ago, slicklines were considered long and rather simple solid wires carrying equipment down the wellbore. New demands for improved technologies caused this view to change. It opened space for innovation in the designs and consequently brought more features to the products.

Nowadays slicklines and e-lines are not just lowering battery-powered tools down the well, they are also delivering electrical power, commuting control signals, and streaming data from tool string to the surface equipment. These new capabilities are expected to withstand harsh downhole environments which are integral parts of the whole measurement system. The all-included package comprising of optical, electrical, and mechanical capability provided by SlickLight-H and DFOS interrogation units is the reason for Thru Tubing Solutions to adopt Wires&Bytes technology. After some weeks of preparation this approach was finally demonstrated in Pennsylvania in March 2022 showing that all-round slickline design and careful adaptation of existing working equipment leads to efficient operation on well sites.

Along with DFOS data acquisition, electrical signaling and controls of downhole tools, the first deployments made space for more feature enhancements, being the reason for Wires&Bytes to introduce further innovation and new products to its portfolio this year.

SlickLight DFOS logging technology is designed to make a change in Oil&Gas industry. SlickLights, our new fiber optic retrievable cables, enable fast and real-time acquisition over the entire wellbore length and allow decision-making directly on site and remotely within a few hours. We are pleased to know that this technology is resonating with key industry players!

So, another SlickLight has been successfully spooled onto an EXPRO metal winch drum and is ready for deployment to gather data.

If you are interested in this technology, contact us for details.

Also you can watch the recordings of our webinars:

— Casting light on wellbore problems: a SlickLight DFOS solution

— SlickLight-C. Electrically enabled slicklines for real-time downhole telemetry and powering

Wires&Bytes US office is growing and we are happy to welcome new team members Alexander Sachivichik and Thomas Meyer!

Thomas is joining Wires&Bytes as a Business Development Manager having tremendous experience in the Oil&Gas industry and Alex is taking up his duties as a Sales Manager with all his energy and commitment.

Our US team based in Texas will be supporting American customers ensuring a smooth and easy transition to the new generation of well logging technologies and digital oilfields represented by Wires&Bytes products and solutions.

Welcome onboard!

08 Feb 2022

The package solution consisted of 4 km of SlickLight-H (hybrid) supplied by Wires&Bytes, along with the SolaSense monitoring system and software. Thru Tubing Solutions will soon be gathering data from oil-producing wells in Pennsylvania, USA.

The cable was successfully spooled on a deployment reel by a local service company. During the spooling onto the Thru Tubing Solutions logging truck, the cable diameter was monitored utilizing a laser diameter measurement device. The diameter throughout the length only varied by +/- 0.0005”.

The SlickLight family is represented by several lightweight cable designs for well logging and monitoring applications. In comparison to traditional well logging cables these designs have a reduced weight and size while maintaining strength, flexibility, and compatibility with standard slickline fittings and accessories.

SlickLight-H is designed to add DAS and DTS monitoring features on top of electric slickline operation. With SlickLight technology service companies do not need to move the tool strings a lot and spend plenty of time doing so to log the entire length of the well and get accurate data in a short period of time. Since the SlickLight is a sensor over its whole length, DFOS kind of acquisition helps to pinpoint locations of interest, and bring focus quickly there using the traditional tools. This is how cost efficiency and better productivity is achieved.

DFOS interrogation equipment is added parallel to existing electric, or battery powered slickline systems, and software allows processing and visualization of both. This allows service providers to introduce wider range of well logging services with more efficiency now.

Get in touch today and we will be able to advise, supply, install, and support your optimal solution!